परिचय

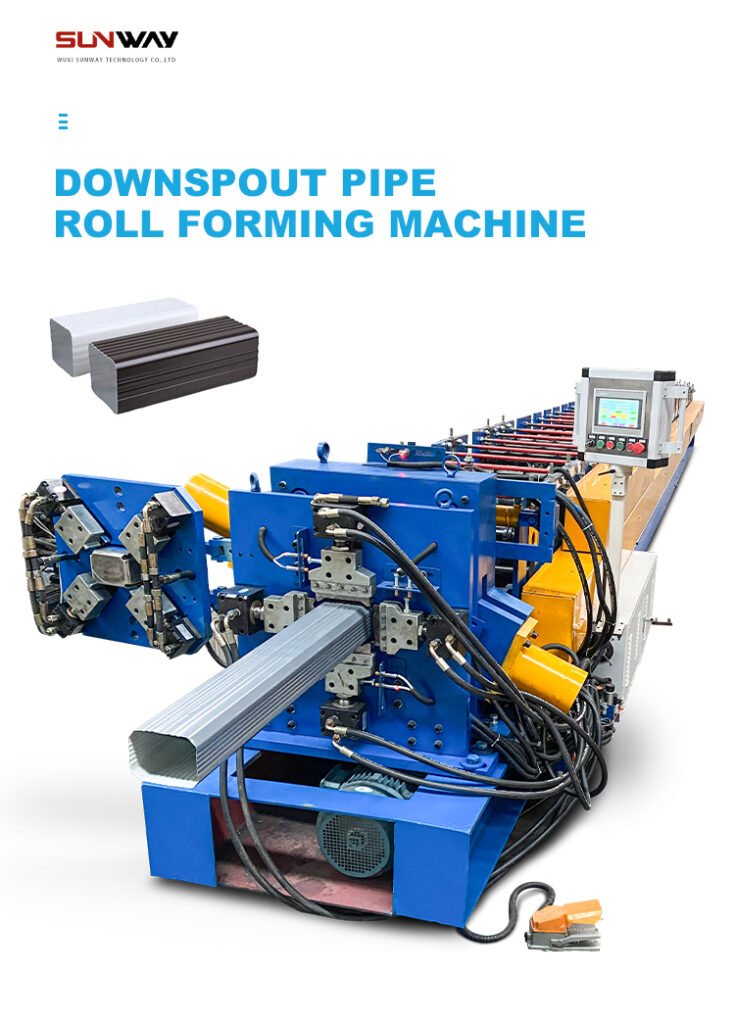

भवनों के लिए गटरों के कुशल विनिर्माण की बात आते ही, हाफ राउंड गटर रोल फॉर्मिंग मशीन निर्माण उद्योग में एक क्रांतिकारी परिवर्तन लाती है। यह क्रांतिकारी प्रौद्योगिकी सटीक इंजीनियरिंग, सामग्री लचीलापन और गति को संयोजित करके असाधारण गुणवत्ता और एकरूपता वाली हाफ राउंड गटर उत्पन्न करती है।

इस लेख में, हम हाफ राउंड गटर रोल फॉर्मिंग मशीनों की दुनिया में गहराई से प्रवेश करेंगे, उनकी विशेषताओं, लाभों, अनुप्रयोगों और अधिक की खोज करेंगे। अंत तक, आपके पास यह व्यापक समझ होगी कि ये मशीनें गटर विनिर्माण के लिए क्यों अपरिहार्य संपत्ति बन गई हैं।

रोल फॉर्मिंग प्रौद्योगिकी को समझना

रोल फॉर्मिंग क्या है?

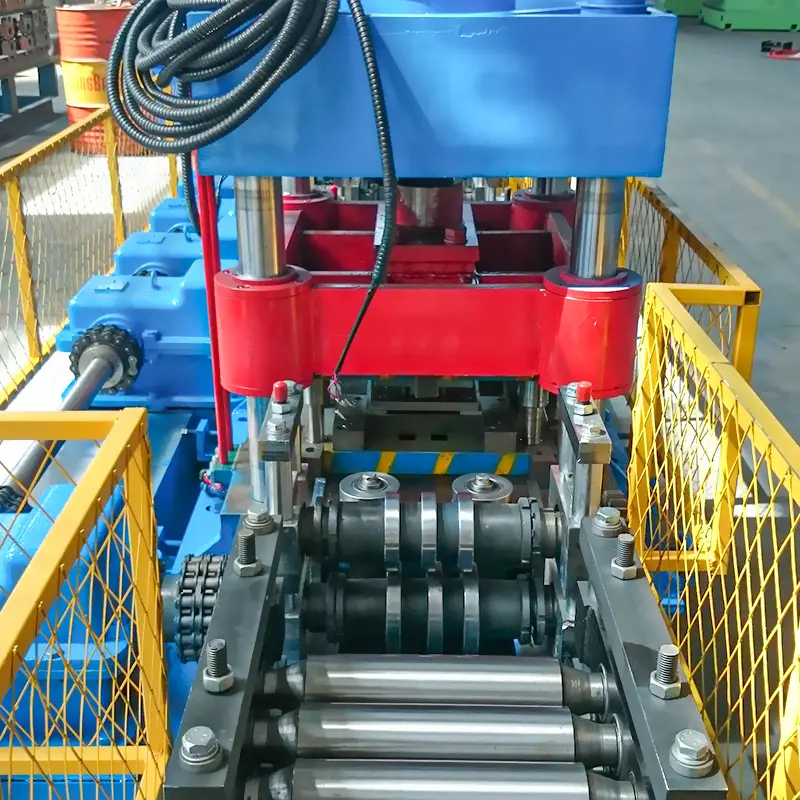

रोल फॉर्मिंग एक धातु निर्माण प्रक्रिया है जो सतत धातु कॉइलों को वांछित प्रोफाइल में आकार देने के लिए उपयोग की जाती है। इस प्रक्रिया में धातु कॉइल को一系列 रोल फॉर्मिंग स्टेशनों से गुजारा जाता है, जहाँ प्रत्येक स्टेशन धातु को क्रमिक रूप से आकार देता है जब तक कि यह अंतिम प्रोफाइल प्राप्त न कर ले।

रोल फॉर्मिंग प्रक्रिया

रोल फॉर्मिंग प्रक्रिया में कई महत्वपूर्ण चरण शामिल हैं, जिनमें सामग्री खिलाना, रोल फॉर्मिंग स्टेशन, कटिंग और कंप्यूटरीकृत नियंत्रण प्रणाली सम्मिलित हैं। ये चरण संयुक्त रूप से सटीक और एकसमान हाफ राउंड गटर बनाते हैं।

हाफ राउंड गटरों की आवश्यकता

हाफ राउंड गटर अपनी सौंदर्य अपील और कार्यात्मक लाभों के कारण लोकप्रिय हो गए हैं। मकान मालिक और निर्माणकर्ता समान रूप से उनके चिकने, वक्रित डिजाइन को विभिन्न वास्तुशिल्प शैलियों के साथ पूरक बनाने के लिए पसंद करते हैं। ये गटर कुशलतापूर्वक वर्षा जल को निर्देशित करते हैं, जल क्षति को रोकते हैं और बेहतर जल प्रवाह सुनिश्चित करते हैं।

हाफ राउंड गटर रोल फॉर्मिंग मशीन की विशेषताएँ

उच्च परिशुद्धता विनिर्माण

रोल फॉर्मिंग प्रक्रिया हाफ राउंड गटरों को आकार देने में उच्च परिशुद्धता सुनिश्चित करती है। मशीन लगातार सटीक माप वाली गटर उत्पन्न कर सकती है, जो प्रत्येक स्थापना के लिए पूर्ण फिट सुनिश्चित करती है।

定制选项

हाफ राउंड गटर रोल फॉर्मिंग मशीनें विविध परियोजना आवश्यकताओं को पूरा करने के लिए अनुकूलन विकल्प प्रदान करती हैं। निर्माणकर्ता विभिन्न आकारों, सामग्रियों और रंगों में से चुन सकते हैं, जिससे वे भवन की सौंदर्य के अनुरूप गटर बना सकें।

Material Flexibility

The roll forming machine accommodates a wide array of materials, including aluminum, steel, copper, and others. This versatility enables superior adaptation to diverse weather conditions and architectural requirements.

गति और दक्षता

Leveraging automated processes and cutting-edge technology, half-round gutter roll forming machines produce gutters at remarkable speeds. This efficiency saves time while lowering labor costs.

半圆形水槽辊压成型机的工作原理

线圈进料系统

整个过程从将金属线圈送入机器开始。线圈进料系统确保材料连续平稳流动,从而最大限度减少生产停机时间。

Roll Forming Stations

机器的核心在于其辊压成型站。这些成型站通过一系列辊轮和模具,逐步将金属塑造成半圆形轮廓。

Mekanisme Pemotong

金属成型为所需形状后,切割机构将水槽切割成指定长度。这样,每段水槽均可直接安装,无需进一步修改。

计算机化控制系统

整个过程由计算机化控制系统主导,可精确调控生产各方面。操作员可调整参数并监控过程,以实现最佳效果。

使用半圆形水槽辊压成型机的优势

Cost Savings

通过自动化水槽制造过程,半圆形水槽辊压成型机显著降低劳动力成本。此外,高效利用材料减少废料,从而实现整体成本节约。

: Collect/output.

辊压成型技术的精密性确保每条水槽质量一致。建筑商和房主可信赖这些符合严格质量标准的水槽。

अपशिष्ट में कमी

传统水槽制造方法往往导致大量材料浪费。辊压成型机通过优化材料利用最小化废料,实现更可持续的生产方式。

更快的生产速度

半圆形水槽辊压成型机的高速生产能力加速制造过程。此速度特别适用于大规模项目和紧迫截止期限。

半圆形水槽的应用

住宅建筑

半圆形水槽因其经典优雅外观而成为住宅建筑的热门选择。它们为任何房屋增添一丝精致,提升外观吸引力。此外,其高效排水性能保护地基、景观和外墙免受水损害。

商业建筑

商业建筑往往有独特的建筑需求,半圆形水槽完美契合这些设计。它们广泛应用于办公室、购物中心、酒店和餐厅等场所,在美观与功能间取得平衡。

历史修复项目

半圆形水槽常用于历史修复项目,以保留老建筑的真实性和魅力。这些水槽既呼应原有建筑设计,又提供现代功能。

选择合适的半圆形水槽辊压成型机

Machine Specifications

选购半圆形水槽辊压成型机时,必须考虑机器规格,如生产速度、材料兼容性和生产不同水槽轮廓的能力。

Durability and Reliability

投资一台坚固可靠的机器对确保连续生产和长期性能至关重要。高品质材料和成熟工程设计的机器提供更高的耐用性和稳定性。

After-Sales Support

信誉良好的制造商应提供全面售后支持,包括技术援助、维护服务和易得备件,从而确保机器全程高效运行。

用户友好界面

直观的用户友好界面简化机器操作。即使经验水平不同的操作员也能快速熟练掌握。

维护与保养以延长使用寿命

定期检查

定期检查有助于识别机器部件的磨损。常规检查和维护可防止故障并延长机器寿命。

स्नेहन

适当润滑运动部件确保平稳运行并减少摩擦磨损。润滑还有助于防止腐蚀。

清洁与去除杂物

保持机器清洁无杂物有助于维持其效率。定期清洁确保无材料堆积干扰制造过程。

维修与服务

及时处理机械问题并在需要时寻求专业服务,可防止小问题演变为重大故障。

安全注意事项

Training and Certification

操作员应接受彻底培训,安全操作半圆形水槽辊压成型机。认证程序确保操作员熟练掌握机器。

机器的安全特性

现代半圆形水槽辊压成型机配备紧急停止按钮和防护罩等安全特性。这些特性在操作中保护操作员免受潜在危害。

व्यक्तिगत सुरक्षात्मक उपकरण (पीपीई)

操作员始终应佩戴适当个人防护装备,如手套、安全眼镜和耳罩,以最小化事故风险。

水槽制造的未来

प्रौद्योगिकीय प्रगति

随着技术不断演进,半圆形水槽辊压成型机预计将更先进高效。创新特性和自动化将进一步简化生产过程。

可持续性与环保材料

随着可持续性日益重视,未来水槽制造将融入环保材料和节能工艺。

常见问题解答(FAQ)

What are half round gutters made of?

Half round gutters can be made from various materials, including aluminum, steel, copper, and vinyl. Each material offers unique properties and benefits.

Can I produce gutters with unique profiles using the machine?

Yes, modern half round gutter roll forming machines offer customization options, allowing you to produce gutters with unique profiles to meet specific project requirements.

Is the roll forming machine suitable for small-scale production?

Yes, half round gutter roll forming machines are versatile and can cater to both small-scale and large-scale production requirements.

How long does it take to set up the machine for a different gutter profile?

Setting up the machine for a different gutter profile typically requires a short amount of time, as modern machines feature easy and quick changeover mechanisms.

What is the typical lifespan of a half round gutter roll forming machine?

With proper maintenance and care, a well-built half round gutter roll forming machine can have a lifespan of many years, providing excellent return on investment.

निष्कर्ष

The half round gutter roll forming machine has revolutionized the way gutters are manufactured, offering precision, efficiency, and customization options. Its role in enhancing water management and protecting buildings from potential damage makes it an indispensable tool in the construction industry.

As technology continues to advance, we can expect these machines to become even more efficient, sustainable, and user-friendly, further contributing to the growth of the gutter manufacturing sector.