परिचय

雨水槽在保护建筑物免受水损害方面发挥关键作用,通过高效地将雨水从屋顶和地基引走。为了满足对高质量且成本效益高的雨水槽日益增长的需求,制造商转向先进技术,如 गटर रोल बनाने की मशीन。本文将探索雨水槽辊压成型机的世界,包括其工作原理、优势、类型及选择合适机器的关键因素。

गटर रोल बनाने की मशीन क्या है?

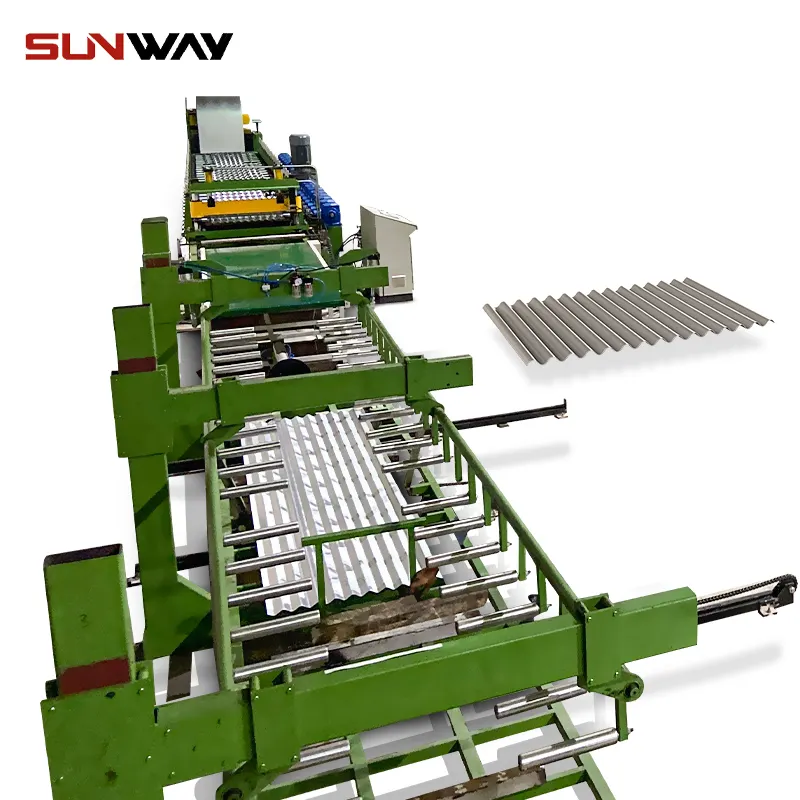

雨水槽辊压成型机是一种工业设备,设计用于生产具有一致横截面型材的无缝雨水槽。它采用连续弯曲工艺,将平板卷材(如铝、钢或铜)转化为各种形状和尺寸的定制雨水槽。该机器设计确保精密准确,材料浪费最小。

雨水槽辊压成型机的优势

Precision and Consistency

雨水槽辊压成型机采用计算机控制系统,确保整个生产过程中型材精密一致。这种精确度保证每个雨水槽段完美契合,降低泄漏和水损害风险。

गति और दक्षता

与传统雨水槽制造方法相比,辊压成型机生产速度显著更快。连续生产工艺最小化停机时间,提升生产力和订单履行速度。

Efektivitas Biaya

尽管雨水槽辊压成型机的初始投资较高,但长期成本节约显著。这些机器消除外包生产需求,节省劳动力和运输成本。

定制选项

雨水槽辊压成型机提供极大灵活性,允许制造商生产各种形状、尺寸和颜色的雨水槽,从而满足不同客户偏好和市场需求。

Reduced Material Waste

辊压工艺优化材料利用率,废料极少。制造商可从相同原料中生产更多雨水槽,降低整体生产成本和环境影响。

雨水槽辊压成型机的工作原理

雨水槽辊压成型机的操作涉及几个关键步骤:

सामग्री खिलाना

过程从装载所需材料卷材(如铝或钢)开始。卷材送入辊压系统,进行连续成型。

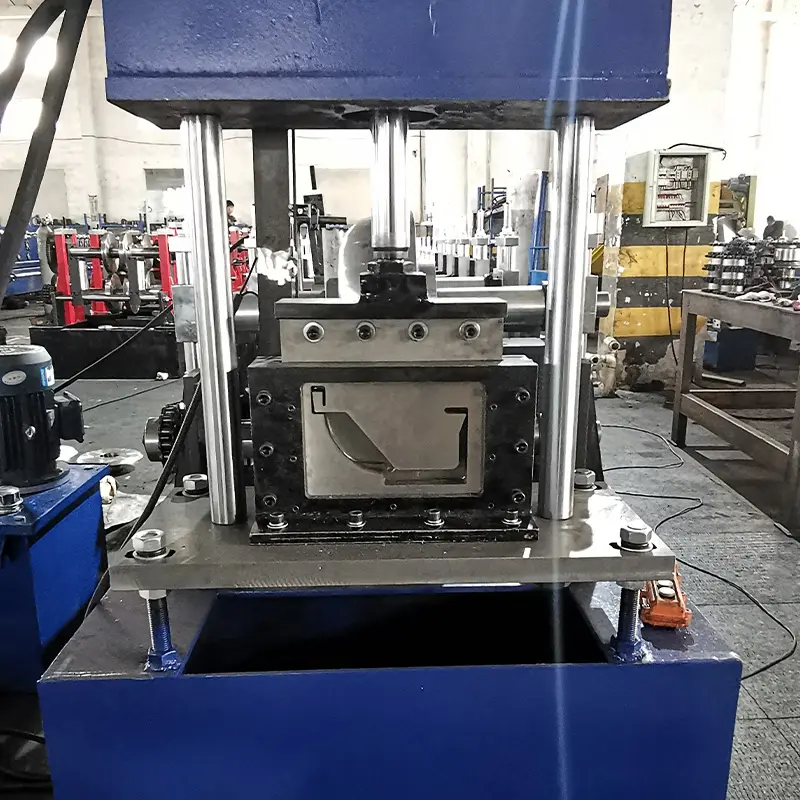

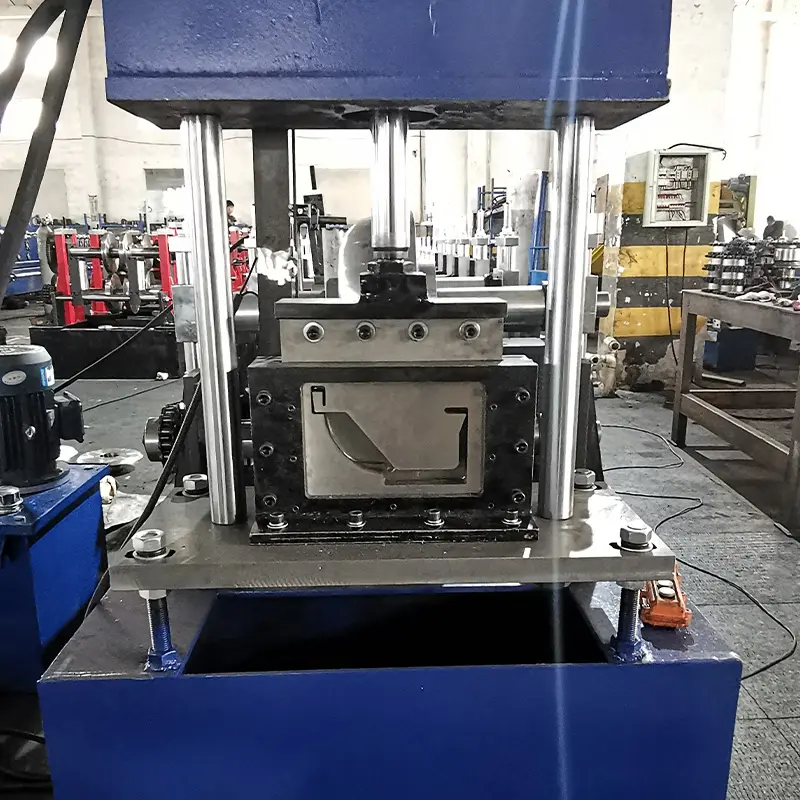

辊压工艺

雨水槽辊压成型机的核心是一系列辊子,逐步将平板卷材弯曲成所需雨水槽形状。辊子根据特定雨水槽型材精心配置。

कटिंग और शीयरिंग

型材成型后,机器自动将雨水槽段切割至所需长度。剪切机构确保切割干净精确。

स्टैकिंग और पैकेजिंग

成品雨水槽段随后堆垛并包装,便于运输和交付客户。

गटर रोल बनाने की मशीन के प्रकार

雨水槽辊压成型机有多种类型,每种针对特定制造需求:

单辊雨水槽机

单辊机适用于生产简单雨水槽型材,成本效益高,适合中小规模生产。

双辊雨水槽机

双辊机提供增强成型能力,允许制造商以更高精度生产复杂雨水槽设计。

K型雨水槽机

K型雨水槽机专为生产流行K形雨水槽设计,广泛用于住宅和商业建筑。

选择雨水槽辊压成型机时需考虑的因素

为企业选择合适的雨水槽辊压成型机需仔细考虑以下因素:

Material Thickness and Width

确保所选机器能处理雨水槽生产所需的特定材料厚度和宽度。

速度与生产能力

评估机器生产速度和产能,确定是否满足制造需求。

型材定制

如需生产多种型材雨水槽,选择易于型材定制的机器。

Machine Size and Space Requirements

考虑工厂可用空间,选择合适尺寸的雨水槽辊压成型机。

Anggaran dan Pertimbangan Biaya

预算虽重要,但应优先品质和可靠性,而非最低价格。从可靠制造商投资知名机器,确保长期生产力。

维护与故障排除

Regular Maintenance Checks

对雨水槽辊压成型机进行常规维护,包括清洁、润滑和关键组件检查,以保持最佳状态。

सामान्य समस्याएं और समाधान

熟悉操作中可能出现的常见问题,并掌握高效排查方法,以最小化停机时间。

操作雨水槽辊压成型机的安全注意事项

Training and Certification

确保操作员接受适当培训和认证,以安全高效操作机器。

व्यक्तिगत सुरक्षात्मक उपकरण (पीपीई)

强制使用合适个人防护装备,如手套、安全眼镜和耳罩,保护操作员免受潜在危害。

机器护罩与安全功能

检查雨水槽辊压成型机是否配备安全护罩和紧急停止功能,以防事故。

材料正确处理

培训操作员小心处理材料,避免手或其他身体部位伸入机器危险区域。

雨水槽辊压成型机的应用

雨水槽辊压成型机在各种建筑项目中广泛应用:

आवासीय निर्माण

雨水槽辊压成型机广泛用于住宅项目,实现无缝雨水槽安装,提升外观吸引力并保护房屋免受水损害。

商业建筑

Commercial properties benefit from the durability and efficiency of gutters produced by roll forming machines, providing effective drainage solutions.

Industrial Projects

Industrial buildings with large roof surfaces rely on gutter roll forming machines to produce gutters that efficiently manage rainwater runoff.

गटर रोल फॉर्मिंग तकनीक में उभरते रुझान

नवाचार लगातार गटर रोल फॉर्मिंग उद्योग को आकार दे रहे हैं:

Automation and Robotics

स्वचालन और रोबोटिक एकीकरण उत्पादकता बढ़ाते हैं, त्रुटियों को कम करते हैं तथा मैनुअल श्रम की आवश्यकता घटाते हैं।

Integration with CAD/CAM Software

सॉफ्टवेयर एकीकरण डिजाइन प्रक्रिया को सुव्यवस्थित करता है, जो डिजाइन और उत्पादन चरणों के बीच सहज संचार सक्षम बनाता है।

टिकाऊ सामग्रियां और प्रथाएं

निर्माता पर्यावरणीय प्रभाव को कम करने के लिए पर्यावरण-अनुकूल सामग्रियों और ऊर्जा-कुशल प्रथाओं की खोज कर रहे हैं।

选择合适的制造商

गटर रोल फॉर्मिंग मशीन निर्माता का चयन करते समय, इन कारकों पर विचार करें:

प्रतिष्ठा और अनुभव

गुणवत्ता वाली रोल फॉर्मिंग मशीनें उत्पादित करने में मजबूत प्रतिष्ठा और व्यापक अनुभव वाले निर्माता का चयन करें।

ग्राहक समीक्षाएँ और प्रशंसापत्र

निर्माता के ग्राहक संतुष्टि स्तर का आकलन करने के लिए वर्तमान और पूर्व ग्राहकों की प्रतिक्रिया की समीक्षा करें।

After-Sales Support and Service

सुनिश्चित करें कि निर्माता मशीन संचालन के दौरान उत्पन्न होने वाली किसी भी समस्या को हल करने के लिए विश्वसनीय बिक्री-उत्तर सहायता और सेवा प्रदान करता हो।

वारंटी और रिटर्न नीतियां

अपनी निवेश की रक्षा के लिए निर्माता द्वारा प्रदान की गई वारंटी कवरेज और रिटर्न नीतियों की जांच करें।

निष्कर्ष

गटर रोल फॉर्मिंग मशीनों ने अपनी सटीकता, दक्षता और अनुकूलन क्षमताओं से गटर निर्माण उद्योग में क्रांति ला दी है। अब निर्माता उच्च-गुणवत्ता वाले गटर तेजी से और अधिक लागत-प्रभावी ढंग से उत्पादित कर सकते हैं, जो विभिन्न निर्माण परियोजनाओं की मांगों को पूरा करते हैं। गटर रोल फॉर्मिंग मशीन चुनते समय, अपनी उत्पादन आवश्यकताओं का सावधानीपूर्वक मूल्यांकन करें, सुरक्षा उपायों पर विचार करें तथा गटर उद्योग में दीर्घकालिक सफलता के लिए प्रतिष्ठित निर्माता में निवेश करें।

常见问题解答

गटर रोल फॉर्मिंग मशीन की सामान्य आयु क्या होती है?

गटर रोल फॉर्मिंग मशीन की आयु रखरखाव, उपयोग की आवृत्ति तथा घटकों की गुणवत्ता सहित विभिन्न कारकों पर निर्भर करती है। उचित देखभाल से ये मशीनें कई वर्षों तक चल सकती हैं।

क्या गटर रोल फॉर्मिंग मशीन विभिन्न आकारों के गटर उत्पादित कर सकती है?

हां, अधिकांश आधुनिक गटर रोल फॉर्मिंग मशीनें अनुकूलन विकल्प प्रदान करती हैं, जो निर्माताओं को ग्राहक आवश्यकताओं को पूरा करने के लिए विभिन्न आकारों और शैलियों के गटर उत्पादित करने की अनुमति देती हैं।

गटर रोल फॉर्मिंग मशीन चलाने के लिए कितनी ट्रेनिंग की आवश्यकता होती है?

ऑपरेटरों को गटर रोल फॉर्मिंग मशीन को सुरक्षित और प्रभावी ढंग से चलाने के लिए व्यापक प्रशिक्षण से गुजरना चाहिए और प्रमाणन प्राप्त करना चाहिए। प्रशिक्षण की अवधि मशीन की जटिलता के आधार पर भिन्न हो सकती है।

क्या गटर रोल फॉर्मिंग मशीनें विभिन्न प्रकार की सामग्रियों को संभाल सकती हैं?

हां, गटर रोल फॉर्मिंग मशीनें एल्यूमीनियम, स्टील और तांबा जैसी विभिन्न सामग्रियों को संभाल सकती हैं। मशीन के रोलर्स और सेटिंग्स उपयोग की जा रही सामग्री के आधार पर समायोजित किए जाते हैं।

क्या गटर रोल फॉर्मिंग मशीनें ऊर्जा-कुशल हैं?

आधुनिक गटर रोल फॉर्मिंग मशीनें अक्सर ऊर्जा-कुशल विशेषताओं को शामिल करती हैं, जो उन्हें समय के साथ अधिक टिकाऊ और लागत-प्रभावी बनाती हैं।