परिचय

In this article, we explore the fascinating world of light gauge steel roll forming machines. These machines play a vital role in producing diverse profiles for construction, manufacturing, and other sectors. We delve into their working principles, advantages, applications, and components. We also cover selection factors, maintenance tips, optimization strategies, case studies, and future trends. Let us dive in!

What is a Light Gauge Steel Roll Forming Machine?

A light gauge steel roll forming machine converts flat steel sheets into consistent cross-section profiles for construction, automotive, furniture, and more via continuous bending through sequential rollers.

How Does a Light Gauge Steel Roll Forming Machine Work?

The process unfolds in stages to shape flat sheets into profiles:

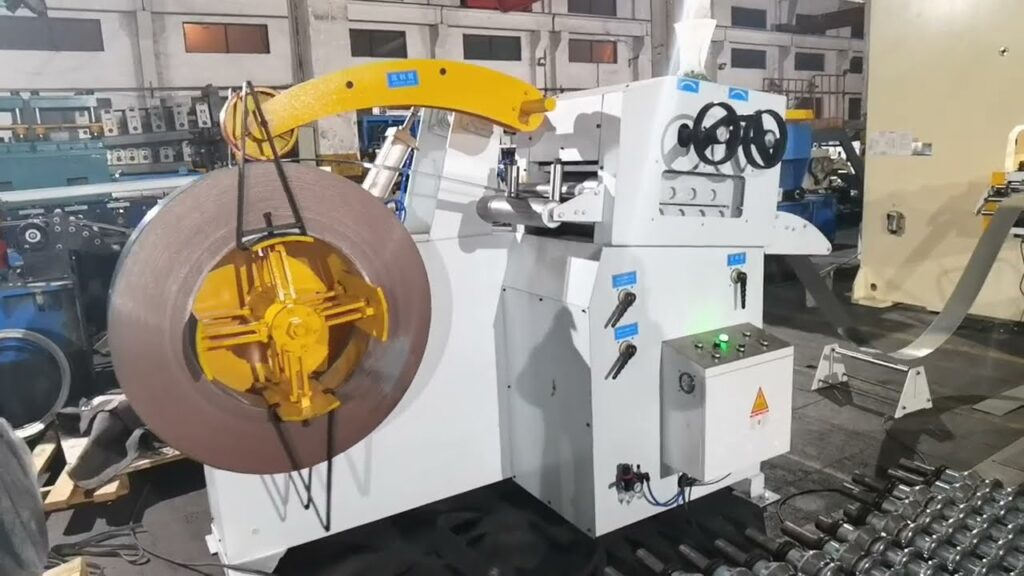

- 开卷: Decoiling unwinds and feeds the metal coil.

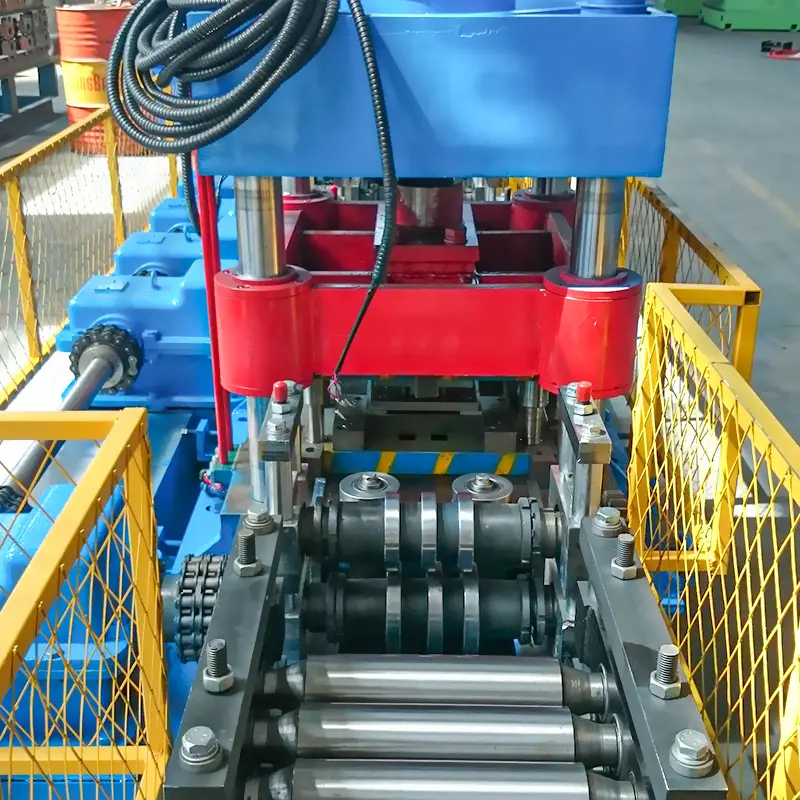

- रोल फॉर्मिंग स्टेशन: Rollers in the forming station progressively bend the sheet.

- कट-ऑफ सिस्टम: Cut-off separates finished profiles via shearing, sawing, or punching.

- 控制系统: Controls oversee coordination, cutting, and parameters.

- Stacker: Profiles are stacked for handling or packaging.

Continuous operation yields high-speed, precise production.

Advantages of Using a Light Gauge Steel Roll Forming Machine

लागत-प्रभावी उत्पादन

Cost-effectiveness stems from material efficiency, minimal waste, high speeds, and automation, slashing labor and total costs.

High Precision and Accuracy

Computer controls ensure uniform dimensions and tolerances for quality profiles.

Versatility in Design and Flexibility

Enables complex, custom profiles in varied thicknesses for architecture and more.

Efficient Production Speed

Surpasses press-brake or extrusion with rapid, continuous output for high-volume needs.

Applications of Light Gauge Steel Roll Forming Machines

Widely used across industries:

- Construction: Profiles form walls, roofs, floors, and framing in buildings.

- Automotive Manufacturing: Components include frames, chassis, doors, and seats.

- Furniture Production: Custom profiles add support, durability, and style.

- Appliance Manufacturing: Used in refrigerators, ovens, washers, and AC units.

- Infrastructure Projects: Supports bridges, stadiums, stations, and airports.

Factors to Consider When Choosing a Light Gauge Steel Roll Forming Machine

Key selection criteria:

Machine Size and Capacity

Match production capacity to profile sizes and volumes.

सामग्री संगतता

Verify material compatibility, including steel grades and thicknesses.

定制选项

Seek customization for specific designs.

Automation and Integration

Opt for auto-feeding, cutting, and stacking to boost efficiency.

Maintenance and Support

Assess maintenance ease and support availability.

These factors ensure optimal choice.

Common Types of Profiles Produced by Light Gauge Steel Roll Forming Machines

Diverse profiles include:

C Channels

C-sections for framing, purlins, joists.

Z Sections

Zigzag for purlins, studs, joists.

Hat Sections

Hat channels for framing, ceilings, claddings.

U Channels

U-shapes for frames and protection.

Sigma Sections

Σ-shapes for beams, columns, trusses.

Many more custom profiles possible.

Key Components of a Light Gauge Steel Roll Forming Machine

Essential parts:

डेकोइलर

Decoiler feeds the coil.

Roll Forming Station

Rollers shape the sheet.

Cut-off System

Separates profiles.

नियंत्रण प्रणाली

Control system manages operations.

Stacker

Handles output.

Integrated for seamless production.

लाइट गेज स्टील रोल फॉर्मिंग मशीनों की देखभाल और रखरखाव

लाइट गेज स्टील रोल फॉर्मिंग मशीन की दीर्घायु और इष्टतम प्रदर्शन के लिए उचित रखरखाव और देखभाल आवश्यक है। यहां कुछ रखरखाव युक्तियां दी गई हैं:

नियमित निरीक्षण और सफाई

पहनाव, क्षति या गलत संरेखण के किसी भी संकेत की पहचान करने के लिए नियमित निरीक्षण करें। मशीन को नियमित रूप से साफ करें ताकि मलबा हटाया जा सके और प्रदर्शन प्रभावित करने वाले जमाव को रोका जा सके।

润滑与加油

मशीन के गतिशील भागों का उचित स्नेहन घर्षण और पहनाव को कम करने के लिए महत्वपूर्ण है। स्नेहन अंतरालों और अनुशंसित स्नेहकों के लिए निर्माता के दिशानिर्देशों का पालन करें।

खराब भागों का प्रतिस्थापन

मशीन के घटकों की स्थिति की निगरानी करें और किसी भी खराब या क्षतिग्रस्त भागों को तुरंत बदलें। इससे मशीन इष्टतम दक्षता से कार्य करती है और खराबी का जोखिम कम होता है।

सुरक्षा उपाय

सुरक्षा प्रोटोकॉल का पालन करें और सुनिश्चित करें कि मशीन की सुरक्षा सुविधाएं कार्यशील हों। ऑपरेटरों को मशीन संचालन की उचित ट्रेनिंग दें और उन्हें व्यक्तिगत सुरक्षात्मक उपकरण प्रदान करें।

इन रखरखाव और देखभाल प्रक्रियाओं का पालन करके, आप अपनी मशीन की आयु को अधिकतम कर सकते हैं और उत्पादन में व्यवधान को न्यूनतम रख सकते हैं।

लाइट गेज स्टील रोल फॉर्मिंग मशीन से उत्पादन को अनुकूलित करने के युक्तिप点

लाइट गेज स्टील रोल फॉर्मिंग मशीन से उत्पादन को अनुकूलित करने के लिए, निम्नलिखित युक्तियों पर विचार करें:

सामग्री चयन

अनुप्रयोग आवश्यकताओं के आधार पर अपनी प्रोफाइलों के लिए उपयुक्त सामग्री चुनें। मजबूती, जंग प्रतिरोध और लागत प्रभावशीलता जैसे कारकों पर विचार करें।

Machine Calibration

प्रोफाइलों को सटीक आयामों के साथ उत्पादित करने के लिए मशीन को नियमित रूप से कैलिब्रेट करें। रोलर संरेखण, कटिंग तंत्र और नियंत्रण प्रणाली की जांच करें ताकि सटीकता बनी रहे।

ऑपरेटर प्रशिक्षण और कौशल विकास

मशीन ऑपरेटरों को व्यापक प्रशिक्षण प्रदान करें, ताकि वे मशीन के संचालन और कार्यक्षमता को समझ सकें। निरंतर प्रशिक्षण कार्यक्रमों के माध्यम से कौशल विकास को बढ़ावा दें ताकि वे मशीन को प्रभावी ढंग से संचालित करने में निपुण हो सकें।

गुणवत्ता नियंत्रण उपाय

उत्पादन प्रक्रिया भर में कड़े गुणवत्ता नियंत्रण उपाय लागू करें। आवश्यक विनिर्देशों और मानकों को पूरा करने के लिए नियमित निरीक्षण और परीक्षण करें।

इन अनुकूलन तकनीकों को अपनाकर, आप उत्पादन दक्षता बढ़ा सकते हैं, प्रोफाइलों की गुणवत्ता सुधार सकते हैं और अपव्यय को कम कर सकते हैं।

अध्ययन मामले: लाइट गेज स्टील रोल फॉर्मिंग मशीनों का सफल कार्यान्वयन

लाइट गेज स्टील रोल फॉर्मिंग मशीनों के सफल कार्यान्वयन को उजागर करने वाले कुछ अध्ययन मामलों का अन्वेषण करें:

आवासीय निर्माण

आवासीय निर्माण परियोजनाओं में, लाइट गेज स्टील रोल फॉर्मिंग मशीनों ने फ्रेमिंग प्रक्रिया में क्रांति ला दी है। बिल्डर और ठेकेदार अब दीवार स्टड्स, छत ट्रस और फर्श जोइस्ट्स के लिए रोल-फॉर्म्ड स्टील प्रोफाइलों का उपयोग करते हैं। मशीनों की उच्च सटीकता और गति त्वरित और कुशल निर्माण की अनुमति देती है, जिससे लागत बचत और संरचनात्मक अखंडता में सुधार होता है।

商业建筑

व्यावसायिक भवनों के निर्माण में, जैसे कार्यालय परिसर और शॉपिंग सेंटर, लाइट गेज स्टील रोल फॉर्मिंग मशीनें लोकप्रिय हो गई हैं। ये मशीनें वास्तुकारों और इंजीनियरों की विशिष्ट डिजाइन आवश्यकताओं को पूरा करने वाले अनुकूलित प्रोफाइलों के उत्पादन को सक्षम बनाती हैं। रोल फॉर्मिंग प्रक्रिया की बहुमुखी प्रतिभा जटिल और सूक्ष्म प्रोफाइलों के निर्माण की अनुमति देती है, जो व्यावसायिक संरचनाओं की अद्वितीय सौंदर्य को योगदान देती है।

इंफ्रास्ट्रक्चर परियोजनाएँ

पुलों, रेलवे स्टेशनों और हवाई अड्डों सहित बुनियादी ढांचा परियोजनाओं को लाइट गेज स्टील रोल फॉर्मिंग मशीनों के कार्यान्वयन से लाभ हुआ है। ये मशीनें उच्च मजबूती और संरचनात्मक स्थिरता वाले लंबे स्पैन प्रोफाइलों के उत्पादन को सक्षम बनाती हैं। रोल फॉर्मिंग प्रक्रिया की दक्षता और सटीकता सुनिश्चित करती है कि प्रोफाइल बुनियादी ढांचा परियोजनाओं की कठोर आवश्यकताओं को पूरा करें, टिकाऊ और विश्वसनीय संरचनाएं प्रदान करें।

ये अध्ययन मामले विभिन्न निर्माण परिदृश्यों में लाइट गेज स्टील रोल फॉर्मिंग मशीनों की बहुमुखी प्रतिभा और प्रभावकारिता को प्रदर्शित करते हैं, जो लागत बचत, सुधरी दक्षता और श्रेष्ठ संरचनात्मक प्रदर्शन में उनके योगदान को प्रदर्शित करते हैं।

लाइट गेज स्टील रोल फॉर्मिंग मशीनों में भविष्य के रुझान और नवाचार

लाइट गेज स्टील रोल फॉर्मिंग मशीनों का क्षेत्र तकनीकी प्रगति और उद्योग मांगों से प्रेरित होकर विकसित हो रहा है। यहां कुछ भविष्य के रुझान और नवाचार दिए गए हैं जिन पर नजर रखें:

- उन्नत स्वचालन: स्वचालन लाइट गेज स्टील रोल फॉर्मिंग मशीनों में तेजी से महत्वपूर्ण भूमिका निभाएगा। उन्नत नियंत्रण प्रणालियां, रोबोटिक्स और कृत्रिम बुद्धिमत्ता उच्च स्तर के स्वचालन को सक्षम बनाएंगी, उत्पादन दक्षता सुधारेंगी और मानवीय त्रुटियों को कम करेंगी।

- CAD/CAM सिस्टम के साथ एकीकरण: कंप्यूटर-एडेड डिजाइन (CAD) और कंप्यूटर-एडेड मैन्युफैक्चरिंग (CAM) सिस्टम के साथ एकीकरण डिजाइन-से-उत्पादन प्रक्रिया को सुव्यवस्थित करेगा। यह एकीकरण डिजाइन सॉफ्टवेयर और रोल फॉर्मिंग मशीनों के बीच सहज संचार को सुगम बनाएगा, प्रोफाइल विनिर्देशों के कुशल हस्तांतरण को सक्षम करेगा।

- स्मार्ट मैन्युफैक्चरिंग और उद्योग 4.0: लाइट गेज स्टील रोल फॉर्मिंग मशीनें स्मार्ट मैन्युफैक्चरिंग वातावरण में एकीकृत होंगी, जिसमें सेंसर, डेटा विश्लेषण और कनेक्टिविटी शामिल होंगे। यह एकीकरण वास्तविक समय निगरानी, पूर्वानुमानित रखरखाव और उत्पादन प्रक्रियाओं के अनुकूलन को सक्षम बनाएगा।

- विस्तारित सामग्री संगतता: भविष्य की मशीनें उन्नत मिश्र धातुओं और संयोजनों सहित व्यापक सामग्रियों के साथ संगतता प्रदान करेंगी। यह लचीलापन प्रोफाइल डिजाइन के लिए नई संभावनाएं खोलेगा और लाइट गेज स्टील रोल फॉर्मिंग मशीनों के अनुप्रयोगों को विस्तारित करेगा।

ये भविष्य के रुझान और नवाचार उद्योग को आगे बढ़ाएंगे, उन्नत क्षमताएं, सुधरी दक्षता और अधिक अनुकूलन विकल्प प्रदान करेंगे।

निष्कर्ष

लाइट गेज स्टील रोल फॉर्मिंग मशीनें निर्माण, विनिर्माण और अन्य उद्योगों में उपयोग की जाने वाली विभिन्न प्रोफाइलों के उत्पादन के लिए आवश्यक उपकरण हैं। उनकी सटीकता, गति, बहुमुखी प्रतिभा और लागत प्रभावशीलता उन्हें आधुनिक उत्पादन प्रक्रियाओं में मूल्यवान संपत्ति बनाती हैं। इन मशीनों की कार्यप्रणाली, लाभ, अनुप्रयोगों और रखरखाव आवश्यकताओं को समझकर, निर्माता अपने उत्पादन को अनुकूलित कर सकते हैं और सुसंगत आयामों वाली उच्च गुणवत्ता वाली प्रोफाइलें प्राप्त कर सकते हैं। प्रौद्योगिकी में निरंतर प्रगति और विकसित उद्योग मांगों के साथ, लाइट गेज स्टील रोल फॉर्मिंग मशीनों का भविष्य आशाजनक दिखता है, जो प्रोफाइल उत्पादन में आगे की नवाचार और दक्षता का मार्ग प्रशस्त करता है।

常见问题解答

1. क्या लाइट गेज स्टील रोल फॉर्मिंग मशीन जटिल आकृतियों वाली प्रोफाइलें उत्पादित कर सकती है?

हां, लाइट गेज स्टील रोल फॉर्मिंग मशीन जटिल आकृतियों वाली प्रोफाइलें उत्पादित कर सकती है। रोल फॉर्मिंग प्रक्रिया की लचीलापन सूक्ष्म और अनुकूलित प्रोफाइलों के निर्माण की अनुमति देती है।

2. निर्माण में लाइट गेज स्टील रोल फॉर्मिंग मशीन का उपयोग करने के मुख्य लाभ क्या हैं?

निर्माण में लाइट गेज स्टील रोल फॉर्मिंग मशीन के उपयोग के मुख्य लाभों में लागत प्रभावी उत्पादन, उच्च सटीकता, डिजाइन बहुमुखी प्रतिभा और कुशल उत्पादन गति शामिल हैं।

3. लाइट गेज स्टील रोल फॉर्मिंग मशीन के लिए रखरखाव कितना महत्वपूर्ण है?

लाइट गेज स्टील रोल फॉर्मिंग मशीन के इष्टतम प्रदर्शन और दीर्घायु के लिए उचित रखरखाव महत्वपूर्ण है। नियमित निरीक्षण, सफाई, स्नेहन और खराब भागों का समय पर प्रतिस्थापन आवश्यक रखरखाव प्रक्रियाएं हैं।

4. क्या लाइट गेज स्टील रोल फॉर्मिंग मशीन स्टील के अलावा अन्य सामग्रियों के साथ कार्य कर सकती है?

हालांकि लाइट गेज स्टील रोल फॉर्मिंग मशीनें मुख्य रूप से स्टील प्रोफाइलों के लिए उपयोग की जाती हैं, वे एल्यूमीनियम, तांबा और कुछ मिश्र धातुओं जैसी अन्य संगत सामग्रियों के साथ भी कार्य कर सकती हैं।

5. लाइट गेज स्टील रोल फॉर्मिंग मशीनों में स्वचालन की क्या भूमिका है?

लाइट गेज स्टील रोल फॉर्मिंग मशीनों में स्वचालन महत्वपूर्ण भूमिका निभाता है। यह उत्पादन दक्षता बढ़ाता है, श्रम लागत कम करता है और निर्मित प्रोफाइलों की समग्र सटीकता और सुसंगतता सुधारता है।

Frequently Asked Questions (FAQ)

1) What production speed can modern Light Gauge Steel Roll Forming Machines achieve in 2025?

- Standard lines run 30–80 m/min for 0.5–1.2 mm GI/GA coils; high-end servo lines with flying shear reach 100–120 m/min depending on punching density and profile complexity.

2) How do I improve length accuracy for stud and track profiles?

- Use high-resolution encoders, thermal compensation, and servo flying cut-offs. Inline laser length verification and automatic offset correction can tighten accuracy to ±0.5–0.8 mm (3σ) at 6 m.

3) Can one machine switch between studs, tracks, and furring channels quickly?

- Yes. Cassette tooling and motorized stand positioning with recipe recall often cut changeover to 15–45 minutes. Manual lines may require 90–180 minutes.

4) Which materials and standards should I consider for light gauge profiles?

- Common: ASTM A653/A1003 (US), EN 10346/EN 10169 and EN 1090 (EU), AS/NZS 1397 (AU/NZ). Coatings include Z (GI), ZAM (zinc-aluminum-magnesium), and pre-painted per EN 10169.

5) How does predictive maintenance reduce downtime on roll forming lines?

- Vibration and current monitoring on gearboxes/motors plus vision-based roll wear analytics predict failures days to weeks in advance, improving OEE by 3–7% in typical deployments.

2025 Industry Trends

- Electrification of ancillary systems: Hydraulic-to-electric conversions on punch/cut units reduce energy by 15–30% per 1,000 m produced.

- HSS and ZM coating adoption: Wider use of 550–700 MPa steels and Zn-Mg coatings for corrosion performance with thinner layers.

- Inline quality control: Vision and laser systems validate web/flange dimensions, hole positions, and camber in real time, linked to coil IDs for traceability.

- Digital changeover: Barcode/QR recipe recall with auto roll-gap presets reduces startup scrap and speeds first-article approval.

- Sustainability metrics: Buyers request EPDs and recycled content disclosures for coils; plants track Scope 2 energy per ton and scrap ratio.

Key KPIs for Light Gauge Steel Roll Forming Machines (2025 benchmarks)

| KPI (0.5–1.2 mm GI/GA) | 2023 Typical | 2025 Best-in-Class | Notes/Enablers |

|---|---|---|---|

| Line speed (m/min) | 25–60 | 100–120 | Servo feed + flying shear |

| Length tolerance (3σ, mm @ 6 m) | ±1.0–1.5 | ±0.5–0.8 | Encoder + temp comp + inline laser |

| Changeover time (stud↔track) | 90–180 min | 15–45 min | Cassettes + auto presets |

| Startup scrap (%) | 2.0–3.0 | 0.7–1.5 | Digital recipes + vision QC |

| Energy (kWh/1,000 m) | 55–80 | 38–55 | All-electric actuation |

| OEE (%) | 65–78 | 82–90 | PdM + SMED + fast fault recovery |

Selected sources and further reading:

- ASTM A653/A1003: https://www.astm.org

- EN 10346 / EN 10169: https://standards.cen.eu

- AISI/CFSEI resources for cold-formed steel: https://www.cfsei.org/resources

- U.S. DOE AMO (motors/drives efficiency): https://www.energy.gov/eere/amo

- World Steel Association (sustainability/EPDs): https://worldsteel.org

Latest Research Cases

Case Study 1: Vision-Guided Inline QC for LGS Stud/Track (2024)

- Background: A residential framing supplier experienced camber and flange-height variability causing assembly issues on site.

- Solution: Added dual-camera vision with laser triangulation after pass 8 and pre-cut station; integrated auto feedback to roll-gap and edge guides; implemented SPC dashboards.

- Results: Camber reduced from 1.6 mm/m to 0.6 mm/m; flange-height Cpk improved from 1.2 to 1.8; rework down 52%; OEE up 6.3%.

Case Study 2: Electric Punch + Recipe Presets for Multi-Profile LGS Line (2025)

- Background: Manufacturer producing studs (C75–C150) and tracks had 2–3 hour changeovers and frequent hydraulic downtime.

- Solution: Retrofitted all-electric C-frame punch, barcode-driven recipe recall, automatic stand positioning, and tool cassette system; added energy metering.

- Results: Changeover cut to 32 minutes; unplanned downtime reduced 40%; energy per 1,000 m lowered 24%; length tolerance tightened to ±0.7 mm (3σ) at 90 m/min.

Expert Opinions

- Dr. Anika Müller, Senior Researcher, Cold-Formed Steel, Fraunhofer IBP

- “When moving to 600–700 MPa coils for light gauge framing, add forming passes and increase roll diameters to manage springback and edge cracking. Early-pass over-bending should be minimized.”

- Jason Patel, Director of Automation, LineSense Controls

- “Closed-loop length control with inline lasers and encoder fusion is the fastest ROI upgrade—typically paying back in 6–12 months through scrap and warranty reductions.”

- Laura Kim, Product Manager, Coated Steels, PacificCoil

- “Zinc-magnesium coatings can match or exceed GI corrosion resistance at lower coating weights, but require cleaner rolls and low-residue lubricants to prevent pickup and roll embossing.”

Practical Tools/Resources

- CFSEI technical notes and webinars on light gauge framing: https://www.cfsei.org/resources

- AISI S100 North American Specification for CFS design: https://www.cfsei.org/resources

- EN 10346 / EN 10169 (coated steels) and EN 1090 (execution of steel structures): https://standards.cen.eu

- ASTM A653, A1003 (material/specs for LGS): https://www.astm.org

- NIST SPC tools and measurement software: https://www.nist.gov/services-resources/software

- DOE AMO guides for efficient drives/VFDs: https://www.energy.gov/eere/amo

- Coil weight/length calculators: https://www.onlinemetals.com/en/calculators

- FMEA templates (quality risk control): https://asq.org/quality-resources/fmea

Note: Benchmarks compiled from OEM datasheets, field audits, and trade publications (2023–2025). Validate on your specific Light Gauge Steel Roll Forming Machines, materials, and local codes.

Last updated: 2025-10-21

Changelog: Added 5 targeted FAQs; inserted 2025 trends with KPI table and sources; provided two recent case studies; included expert opinions; compiled practical tools/resources aligned to light gauge steel roll forming machines

Next review date & triggers: 2026-04-21 or earlier if AISI/EN/ASTM standards change, OEMs release next-gen electric punch/cut modules, or energy/OEE benchmarks shift by >10% in industry reports