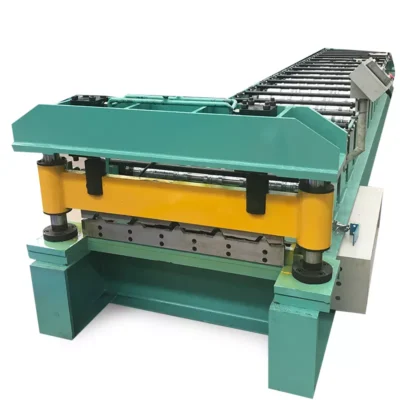

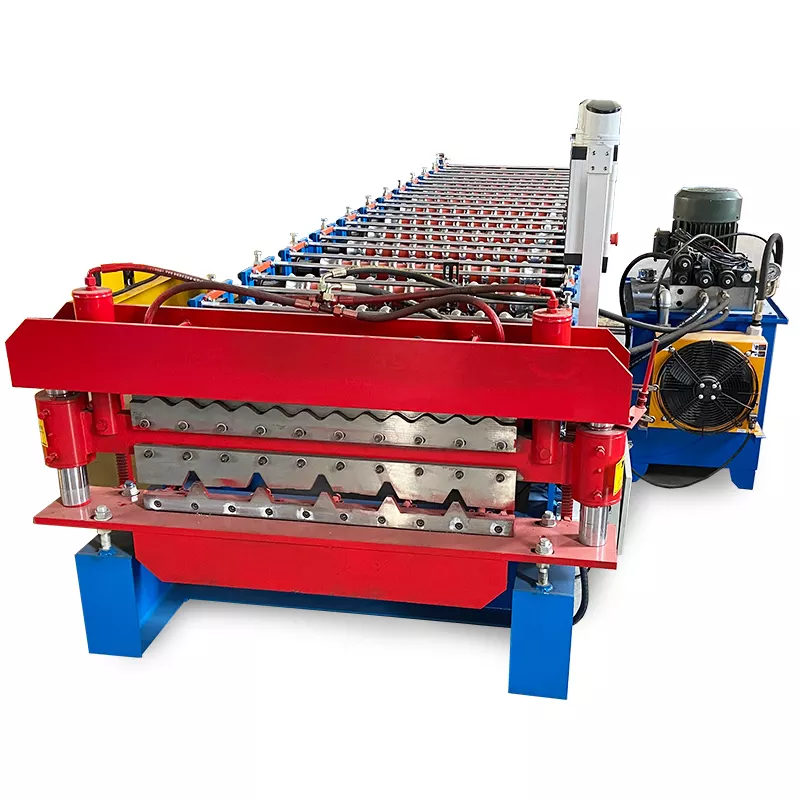

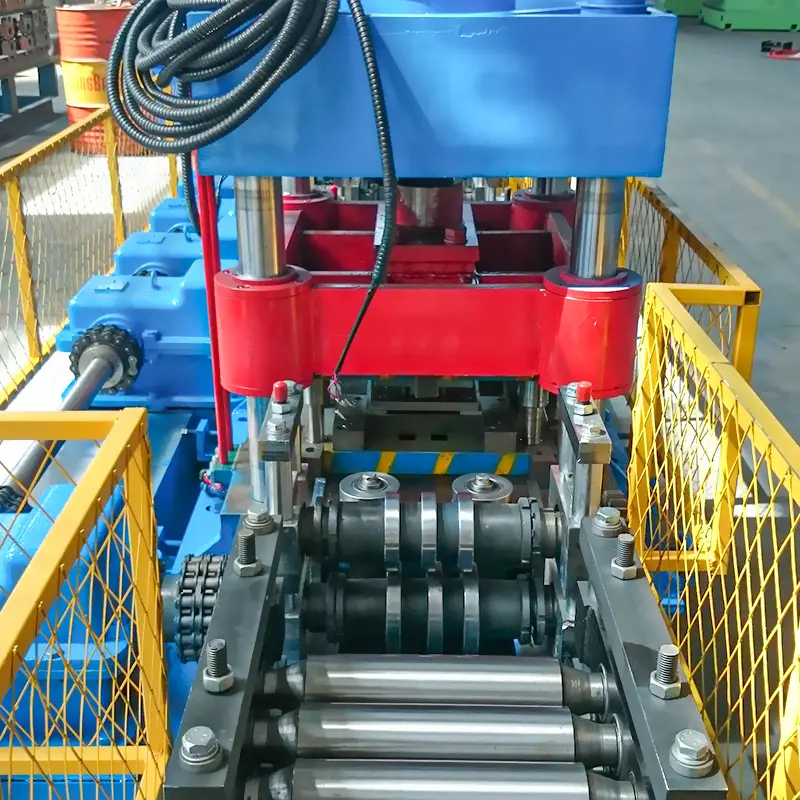

ए mesin pembentuk gulungan lembaran bergelombang विनिर्माण उद्योग में लहरदार धातु शीट्स का उत्पादन करने के लिए उपयोग किया जाने वाला एक उपकरण है। ये मशीनें सपाट धातु शीट्स को लहरदार, धनुषाकार पैटर्न में बदलने के लिए डिज़ाइन की गई हैं जो मजबूती, टिकाऊपन और सौंदर्य अपील प्रदान करती हैं। मशीन सपाट धातु शीट को एक श्रृंखला के रोलर्स से गुजारकर काम करती है जो शीट को धीरे-धीरे मोड़ती और वांछित लहरदार पैटर्न में आकार देती है। परिणामस्वरूप शीट्स का उपयोग विभिन्न अनुप्रयोगों में किया जा सकता है, जिसमें वाणिज्यिक और आवासीय भवनों के लिए छत, साइडिंग और डेकिंग शामिल हैं। लहरदार शीट रोल फॉर्मिंग मशीन के उपयोग से निर्माताओं को अनुकूलन, लागत बचत और बढ़ी हुई दक्षता सहित कई लाभ मिलते हैं।

लहरदार शीट रोल फॉर्मिंग मशीन का अनुकूलन

लहरदार शीट रोल फॉर्मिंग मशीन में निवेश करने से निर्माताओं को विशिष्ट ग्राहक आवश्यकताओं को पूरा करने वाले अनुकूलित उत्पाद बनाने की क्षमता प्राप्त हो सकती है। ऐसा इसलिए है क्योंकि मशीन ग्राहक विनिर्देशों के अनुसार विभिन्न आकारों, आकृतियों और मोटाई वाली शीट्स का उत्पादन कर सकती है। निर्माता अपने उत्पादन प्रक्रिया को प्रत्येक ग्राहक की सटीक आवश्यकताओं के अनुरूप ढाल सकते हैं, जिससे वे प्रतिस्पर्धी बाजार में अलग दिख सकें।

आकार और आकृति अनुकूलन के अलावा, लहरदार शीट रोल फॉर्मिंग मशीन विभिन्न कोटिंग्स और फिनिश वाली शीट्स भी उत्पादित कर सकती है। उदाहरण के लिए, निर्माता विभिन्न पेंट रंगों वाली शीट्स का उत्पादन कर सकते हैं या जंग या संक्षारण को रोकने के लिए सुरक्षात्मक कोटिंग लगा सकते हैं। यह अनुकूलन स्तर सुनिश्चित करता है कि अंतिम उत्पाद ग्राहक की विशिषत आवश्यकताओं को पूरा करे और उच्च स्तर की ग्राहक संतुष्टि प्रदान करे।

अनुकूलन के लिए लहरदार शीट रोल फॉर्मिंग मशीन के उपयोग से नए उत्पादों का त्वरित उत्पादन भी संभव होता है, जिससे निर्माताओं को बाजार में प्रतिस्पर्धी बढ़त मिलती है। अनुकूलित उत्पादों का उत्पादन करके, निर्माता नए ग्राहकों को आकर्षित कर सकते हैं और मौजूदा ग्राहकों को बनाए रख सकते हैं, जिससे बिक्री और लाभ में वृद्धि होती है।

कुल मिलाकर, लहरदार शीट रोल फॉर्मिंग मशीन में निवेश करने से निर्माताओं को विशिष्ट ग्राहक आवश्यकताओं को पूरा करने वाले अनुकूलित उत्पाद बनाने की लचीलापन मिल सकता है। इससे निर्माता प्रतिस्पर्धी बाजार में अलग दिख सकते हैं और ग्राहक संतुष्टि तथा वफादारी में वृद्धि हो सकती है।

लागत बचत के लिए लहरदार शीट रोल फॉर्मिंग मशीन का उपयोग

लहरदार शीट रोल फॉर्मिंग मशीन में निवेश करने का एक प्रमुख लाभ यह है कि यह निर्माताओं को लागत बचत प्रदान कर सकती है। इस मशीन के उपयोग से सामग्री के उपयोग को अनुकूलित करके और अपशिष्ट को कम करके उत्पादन लागत को कम किया जा सकता है।

मैनुअल उत्पादन विधियों की तुलना में, एक कोरुगेटेड शीट रोल फॉर्मिंग मशीन कम अवधि में बड़ी मात्रा में शीट्स का उत्पादन कर सकती है। यह बढ़ी हुई उत्पादन क्षमता श्रम लागत को कम करने तथा उच्च उत्पादन प्राप्त करने में सहायक हो सकती है, जिससे प्रति इकाई उत्पादन लागत घट जाती है।

इसके अतिरिक्त, रोल फॉर्मिंग मशीन का उपयोग सामग्री की बर्बादी को न्यूनतम कर सकता है। मशीन को सटीकता से काटने और आकार देने के लिए प्रोग्राम किया जा सकता है धातु शीट्स सटीकता के साथ, जिससे सामग्री का अधिकतम उपयोग सुनिश्चित होता है और बर्बादी कम होती है। इससे समय के साथ सामग्री लागत में उल्लेखनीय कमी आती है, जिससे निर्माताओं को बड़ा लागत बचत प्राप्त होता है।

इसके अलावा, रोल फॉर्मिंग मशीनों को स्टील, एल्यूमीनियम और तांबे सहित विभिन्न धातु सामग्रियों के साथ काम करने के लिए डिज़ाइन किया जा सकता है। यह बहुमुखी प्रतिभा निर्माताओं को अपनी विशिष्ट आवश्यकता के लिए सबसे किफायती सामग्री चुनने की अनुमति देती है, जिससे अतिरिक्त लागत बचत होती है।

कुल मिलाकर, कोरुगेटेड शीट रोल फॉर्मिंग मशीन में निवेश करने से निर्माता सामग्री और उत्पादन लागत पर बचत कर सकते हैं, जिससे लाभ में वृद्धि होती है। यह लागत बचत ग्राहकों को हस्तांतरित की जा सकती है, जिससे अंतिम उत्पाद बाजार में अधिक किफायती और प्रतिस्पर्धी बन जाता है।

समय दक्षता के लिए कोरुगेटेड शीट रोल फॉर्मिंग मशीन का उपयोग

विनिर्माण में कोरुगेटेड शीट रोल फॉर्मिंग मशीन के उपयोग का एक प्रमुख लाभ उच्च मात्रा उत्पादन के लिए उल्लेखनीय समय बचत प्रदान करना है।

मैनुअल उत्पादन विधियों की तुलना में, कोरुगेटेड शीट रोल फॉर्मिंग मशीन कम अवधि में बड़ी मात्रा में शीट्स का उत्पादन कर सकती है। मशीन निरंतर चल सकती है, न्यूनतम मानवीय हस्तक्षेप के साथ कोरुगेटेड शीट्स की स्थिर धारा उत्पन्न करते हुए। यह बढ़ी हुई उत्पादन दक्षता निर्माताओं को कड़े समयसीमाओं को पूरा करने और लीड टाइम कम करने में सहायता कर सकती है।

इसके अलावा, एक रोल फॉर्मिंग मशीन को सटीक आयामों और विनिर्देशों वाली चादरें उत्पादित करने के लिए प्रोग्राम किया जा सकता है, जिससे अतिरिक्त मशीनिंग या फिनिशिंग की आवश्यकता कम हो जाती है। इससे निर्माताओं को महंगे उत्पादन चरणों को समाप्त करने और समग्र उत्पादन समय को कम करने में सहायता मिलती है।

इसके अतिरिक्त, एक कॉरुगेटेड शीट रोल फॉर्मिंग मशीन को स्टील, एल्यूमीनियम और तांबे सहित विभिन्न सामग्रियों के साथ काम करने के लिए डिज़ाइन किया जा सकता है। यह बहुमुखी प्रतिभा निर्माताओं को सामग्रियों के बीच आसानी से और तीव्रता से स्विच करने की अनुमति देती है, जिससे बाजार की बदलती मांगों को पूरा करना सरल हो जाता है।

कुल मिलाकर, कॉरुगेटेड शीट रोल फॉर्मिंग मशीन के उपयोग से प्राप्त समय दक्षता लाभ निर्माताओं को उत्पादन आउटपुट बढ़ाने, लीड टाइम कम करने और ग्राहक मांगों को अधिक कुशलतापूर्वक पूरा करने में सहायता करते हैं। इससे अंततः लाभ में वृद्धि और ग्राहक संतुष्टि में वृद्धि होती है।

कॉरुगेटेड शीट रोल फॉर्मिंग मशीन के उपयोग के लिए गुणवत्ता नियंत्रण

एक कॉरुगेटेड शीट रोल फॉर्मिंग मशीन निरंतर उत्पाद गुणवत्ता सुनिश्चित कर सकती है और मैनुअल उत्पादन में होने वाली त्रुटियों को कम कर सकती है, जिससे निर्माताओं को अपने उत्पादों की गुणवत्ता पर अधिक नियंत्रण प्राप्त होता है।

मैनुअल उत्पादन विधियों के साथ, मानवीय श्रम की निहित परिवर्तनशीलता के कारण सुसंगत उत्पाद गुणवत्ता बनाए रखना कठिन हो सकता है। हालांकि, एक कॉरुगेटेड शीट रोल फॉर्मिंग मशीन सटीक आयामों और विनिर्देशों वाली चादरें उत्पादित कर सकती है, यह सुनिश्चित करते हुए कि प्रत्येक उत्पाद समान गुणवत्ता और सटीकता के स्तर को पूरा करता है।

इसके अलावा, एक रोल फॉर्मिंग मशीन को विभिन्न धातु सामग्रियों के साथ काम करने के लिए डिज़ाइन किया जा सकता है, जिनमें प्रत्येक की अपनी विशेषताएं और गुण होते हैं। इस मशीन को प्रत्येक सामग्री पर उपयुक्त दबाव और आकार देने के लिए प्रोग्राम किया जा सकता है, यह सुनिश्चित करते हुए कि अंतिम उत्पाद वांछित गुणवत्ता मानकों को पूरा करता है।

इसके अतिरिक्त, एक कॉरुगेटेड शीट रोल फॉर्मिंग मशीन मैनुअल उत्पादन में होने वाली त्रुटियों और दोषों को कम करने में सहायता कर सकती है। मशीन को निर्दिष्ट आयामों से विचलन या दोषों का पता लगाने के लिए प्रोग्राम किया जा सकता है, जिससे निर्माता अंतिम उत्पाद तैयार होने से पहले त्रुटियों को सुधार सकें। इससे दोषपूर्ण उत्पादों के उत्पादन का जोखिम कम होता है और गुणवत्ता के लिए उनकी प्रतिष्ठा बनी रहती है।

कुल मिलाकर, कॉरुगेटेड शीट रोल फॉर्मिंग मशीन का उपयोग निर्माताओं को अपने उत्पादों की गुणवत्ता पर अधिक नियंत्रण प्रदान कर सकता है, जिससे मैनुअल उत्पादन में होने वाली त्रुटियों के साथ सुसंगत गुणवत्ता प्राप्त होती है। इससे ग्राहक संतुष्टि और प्रतिधारण में वृद्धि होती है, जो अंततः लाभ में वृद्धि का कारण बनती है।

कॉरुगेटेड शीट रोल फॉर्मिंग मशीन में निवेश करना निर्माताओं के लिए अनुकूलन, लागत बचत, बढ़ी हुई दक्षता और उन्नत उत्पाद गुणवत्ता सहित विविध लाभ प्रदान करता है। ये मशीनें विशिष्ट ग्राहक आवश्यकताओं को पूरा करने वाले अनुकूलित उत्पाद उत्पन्न कर सकती हैं, सामग्री के उपयोग को अनुकूलित करती हैं और अपशिष्ट को न्यूनतम करती हैं, उत्पादन समय को कम करती हैं, तथा त्रुटियों को कम करते हुए सुसंगत उत्पाद गुणवत्ता सुनिश्चित करती हैं। कॉरुगेटेड शीट रोल फॉर्मिंग मशीन में निवेश करके, निर्माता अपनी प्रतिस्पर्धी क्षमता में सुधार कर सकते हैं, लाभ बढ़ा सकते हैं और ग्राहकों को उच्च गुणवत्ता वाले उत्पाद प्रदान कर सकते हैं।