परिचय

Are you in the metal fabrication industry and looking for an efficient and cost-effective way to produce square pipes? Look no further than a square pipe roll forming machine. This advanced piece of equipment allows you to automate the process of creating square pipes with precision and consistency. In this article, we will explore the various aspects of square pipe roll forming machines, including their benefits, working principles, key components, maintenance requirements, and more. So let's dive in!

What is a Square Pipe Roll Forming Machine?

A square pipe roll forming machine is a specialized piece of equipment used in the metalworking industry to manufacture square pipes from flat sheet metal. It employs a continuous bending process where a strip of metal is passed through a series of rolls that gradually shape it into a square pipe profile. The machine uses a combination of rollers, guides, and cutting tools to ensure precise dimensions and a high-quality finish.

Benefits of Using a Square Pipe Roll Forming Machine

Using a square pipe roll forming machine offers several advantages over traditional manufacturing methods. Here are some key benefits:

- Cost Efficiency: Square pipe roll forming machines can produce square pipes at a faster rate and with less material waste compared to other fabrication methods. This leads to significant cost savings in terms of both material and labor.

- High Precision: Roll forming machines provide excellent dimensional accuracy, ensuring consistent square pipe profiles throughout the production process. This precision is essential for applications that require tight tolerances.

- 多功能性: Square pipe roll forming machines can accommodate a wide range of material thicknesses and sizes. By adjusting the machine settings, you can produce square pipes of different dimensions to suit various applications.

- Time Efficiency: Equipped with automated feeding and cutting systems, square pipe roll forming machines enable continuous and highly efficient production of square pipes, saving time and boosting overall productivity.

Applications of Square Pipe Roll Forming Machines

Square pipes produced by roll forming machines serve diverse industries. Key applications include:

- Construction and architecture: Used for building frameworks, support columns, handrails, and fencing.

- Automotive sector: Employed in vehicle frames, chassis parts, and exhaust systems.

- Furniture production: Utilized in frames for tables, chairs, and shelving.

- Electrical enclosures: Form the structural backbone of panels and cabinets.

- Greenhouse structures: Applied in frames and support systems.

How Does a Square Pipe Roll Forming Machine Work?

A square pipe roll forming machine relies on the principle of progressive, continuous bending. Below is a step-by-step overview of its operation:

- Material Feeding: A flat metal strip, typically steel or aluminum, is introduced into the machine. It passes through a sequence of rollers that incrementally form it into a square pipe profile.

- 辊压成型: As the strip advances through the rollers, it undergoes successive bending and shaping stages, with each roller set refining the metal toward the final square configuration.

- Cutting and Length Measurement: Upon reaching the specified length, the machine precisely cuts the pipe. A integrated length measurement system guarantees accuracy.

- Ejection and Stacking: Post-cutting, the finished pipes are discharged and gathered in a stacking zone for subsequent handling or packaging.

Key Components of a Square Pipe Roll Forming Machine

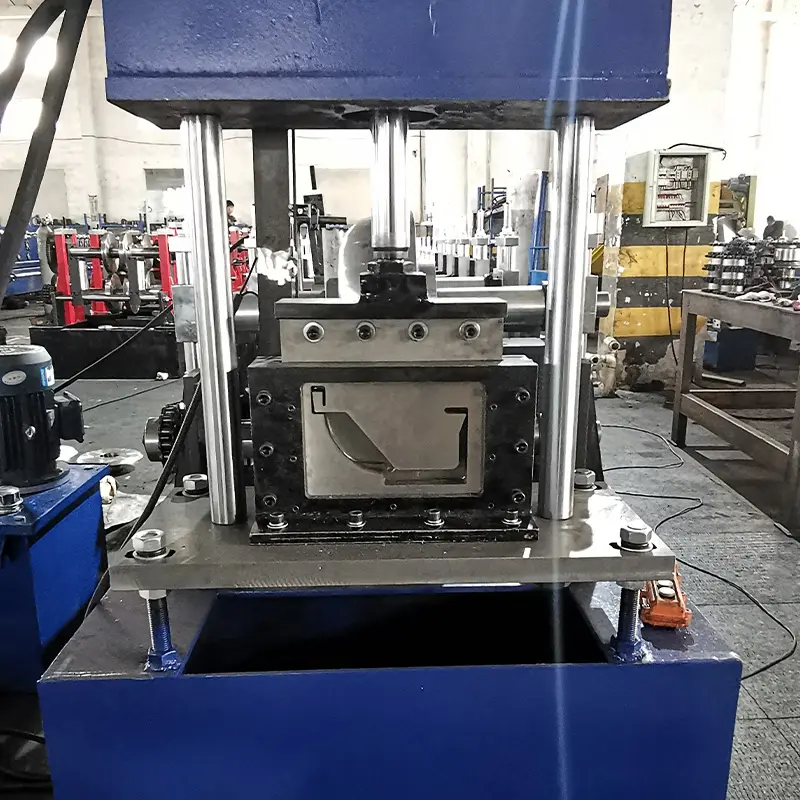

A square pipe roll forming machine integrates several vital components to deliver superior square pipes. Key elements include:

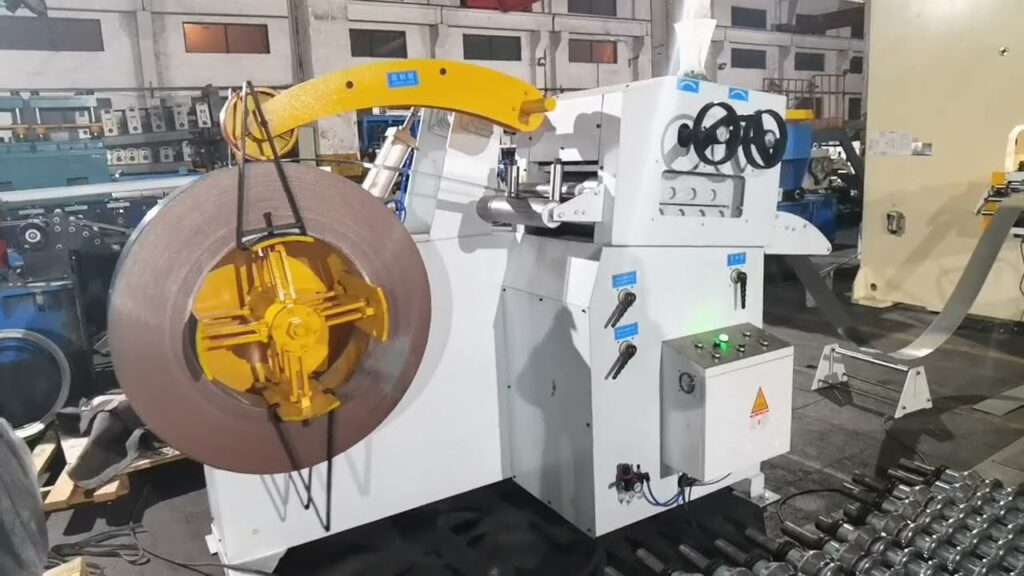

- Decoiler: This unit uncoils and feeds the flat metal strip into the machine, providing uninterrupted material supply throughout the process.

- Roller Stations: Comprising multiple roller sets, these stations progressively bend and form the strip, with each set executing a dedicated shaping task.

- Cutting Mechanism: Responsible for precise length cutting, it employs methods like shearing or sawing.

- 控制系统: The control system includes electrical and electronic elements that oversee and regulate machine functions, enabling exact adjustments to speed, length, and other variables.

- Stacking System: This system gathers completed pipes and organizes them neatly for convenient handling and downstream processing.

Factors to Consider When Choosing a Square Pipe Roll Forming Machine

Selecting the ideal square pipe roll forming machine demands careful evaluation of key factors to align with your business needs. Consider these essentials:

- Material Compatibility: Identify the metals and thicknesses intended for production, ensuring the machine accommodates them effectively.

- Production Volume: Evaluate required output rates and select a machine capable of sustaining that volume.

- 定制选项: If versatility in pipe dimensions is needed, opt for adjustable configurations and tooling.

- Machine Size and Space Requirements: Assess facility space and choose a footprint that integrates seamlessly without limitations.

- Maintenance and Support: Review upkeep needs and vendor support reliability, favoring proven providers.

Maintenance and Care for Square Pipe Roll Forming Machines

Meticulous maintenance is vital for extending the life and peak performance of your square pipe roll forming machine. Adopt these best practices:

- Regular Cleaning: Routinely remove dust, debris, and metal residues to safeguard moving parts and sustain efficiency.

- स्नेहन: Lubricate bearings, gears, and dynamic components per manufacturer guidelines to minimize friction and forestall wear.

- Routine Inspections: Conduct frequent checks for wear, loose fittings, or damage, promptly repairing or replacing parts to uphold reliability and safety.

- Training and Operator Awareness: Train operators thoroughly on procedures and instill safety protocol adherence.

Troubleshooting Common Issues with Square Pipe Roll Forming Machines

Though engineered for dependability, square pipe roll forming machines may encounter occasional challenges. Here are frequent problems and remedies:

- Uneven Bending: Inconsistent profiles signal roller misalignment. Verify and realign stations as required.

- Material Jamming: Jams halt production; inspect feeders for blockages, clear them, and restore smooth flow.

- Cutting Defects: Subpar cuts stem from dull blades or misalignment. Inspect, sharpen or replace blades, and recalibrate measurements.

- Machine Vibrations: Excess vibration impairs quality; secure foundations, tighten bolts, and level properly.

- Electrical Issues: Power or control faults require connection checks; secure wiring and engage electricians if necessary.

- Excessive Noise: Abnormal sounds indicate worn components; inspect, replace, and lubricate accordingly.

For unresolved issues, consult the manufacturer or a specialist. Proactive maintenance, swift repairs, and operator training minimize disruptions for seamless operation.

Tips for Optimal Performance of Square Pipe Roll Forming Machines

Enhance your machine's efficiency with these proven strategies:

- Regular Calibration: Periodically recalibrate for precise dimensions and uniform bending, adjusting settings to uphold profile consistency.

- Quality Control: Enforce rigorous inspections for accuracy, finish, and defects, delivering only premium products.

- Operator Training: Deliver in-depth training on operations, upkeep, and safety to enable quick issue resolution and heightened productivity.

- Optimize Material Usage: Reduce waste through efficient nesting and planning, maximizing yield and cutting costs.

- Continuous Monitoring: Track speed, tension, and alignment via sensors, addressing anomalies swiftly to avert downtime.

These practices elevate performance, durability, and reliability, driving productivity and satisfaction.

Safety Precautions for Operating a Square Pipe Roll Forming Machine

Adhering to safety protocols protects operators and fosters a secure environment. Essential measures include:

- Operator Protection: Mandate PPE like safety glasses, gloves, hearing protection, shoes, and attire to mitigate injury risks.

- Machine Guarding: Fit guards and barriers over hazardous zones like rollers and cutters to prevent inadvertent contact.

- Lockout/Tagout Procedures: Enforce isolation protocols during servicing, with training for all staff.

- Emergency Stop Devices: Install accessible stops and train on their use for immediate halts.

- Risk Assessment: Evaluate hazards and implement controls systematically.

- Regular Maintenance: Maintain safety features like interlocks and sensors through inspections.

Prioritize safety always; these steps ensure a hazard-free workplace.

Future Trends in Square Pipe Roll Forming Technology

Advancements and demands propel ongoing evolution. Watch for these developments:

- Automation and Integration: Robotics and automation will amplify efficiency via automated handling, tool swaps, and inspections.

- Advanced Control Systems: Intuitive interfaces and real-time oversight will simplify setups, diagnostics, and control.

- Advanced Material Handling: Seamless line integration will cut manual work, waste, and boost flow.

- Smart Manufacturing and Data Analytics: IIoT and analytics enable predictive upkeep and optimized decisions for superior performance.

- Energy Efficiency: Sustainable designs incorporate regenerative systems and efficient motors to lower consumption.

These innovations promise greater efficiency, output, and eco-friendliness in metal fabrication.

निष्कर्ष

Square pipe roll forming machines transform production, offering economical, accurate, and streamlined solutions. Grasping benefits, operations, components, and care informs optimal choices.

Prioritize material fit, volume, customization, and support in selection. Maintenance, troubleshooting, and safety ensure dependable use.

Embracing automation, smart controls, and Industry 4.0 elevates capabilities amid evolution.

Leverage this technology to satisfy demand and excel in metalworking.

常见问题解答

1. Is a square pipe roll forming machine suitable for producing other shapes besides square pipes?

Primarily for squares, customization or tooling changes enable rectangles or other profiles.

2. What types of materials can be used with a square pipe roll forming machine?

Compatible metals include:

- Steel: Mild and high-strength variants in various gauges for broad applications.

- Aluminum: Lightweight, corrosion-resistant for weight-sensitive uses like aerospace.

- Stainless Steel: Durable and hygienic for architecture and food processing.

- Copper: Conductive for electrical and plumbing.

Verify machine compatibility with your materials for peak results.

3. Can square pipe roll forming machines produce pipes of different sizes?

Yes, adjustable rollers accommodate varying side lengths and thicknesses.

4. Are square pipe roll forming machines suitable for high-volume production?

Ideal for high output, with continuous automated processes for rapid, efficient runs.

5. Can square pipe roll forming machines be integrated into existing production lines?

Fully integrable, enhancing flow with handling, QC, and downstream systems.

Frequently Asked Questions (FAQ)

1) How do I choose the right forming speed for a Square Pipe Roll Forming Machine?

- Match speed to thickness, alloy, and weld process. Typical ranges: 20–60 m/min for 0.8–2.5 mm steel with HF welding; heavier gauges or dense inline punching may cap at 15–30 m/min to maintain squareness and weld quality.

2) What are the key metrics to monitor for squareness and straightness?

- Across-flats tolerance, corner radius consistency, twist (°/m), bow (mm/m), and weld seam bead height. Inline laser gauges can hold twist ≤0.5°/m and bow ≤1.0 mm/m on 1.2–1.5 mm GI.

3) Which welding method is best for square tube production?

- For carbon steel: Solid-state HF ERW is standard for speed/strength. For stainless and aluminum: GTAW or laser welding delivers cleaner seams but lower line speeds; fiber laser ERW hybrids are emerging for thin-wall SS at 15–25 m/min.

4) How can I reduce edge cracking at corners when forming high-strength steel?

- Increase pass count near the breakdown/fin passes, apply progressive edge conditioning, use larger initial corner radii, optimize lubricant viscosity, and preheat strip edges slightly in cold environments to avoid micro-cracks.

5) What preventive maintenance has the highest ROI?

- Weekly roll cleaning/inspection, weld squeeze roll alignment checks, encoder calibration for cut length, and coolant/filtration management. These steps typically reduce scrap 1–2% and unplanned downtime by 10–20%.

2025 Industry Trends

- All-electric actuation: Servo-driven stands and cutoffs replace hydraulics, cutting energy and oil-related downtime.

- Inline metrology: Affordable laser/vision systems verify twist, bow, and weld bead at speed, enabling closed-loop corrections.

- Advanced coatings and substrates: Zn–Mg (EN 10346 ZM) and high-strength steels (S550–S700) expand thin-wall structural applications.

- AI process tuning: Edge camber compensation and weld power optimization using machine learning on historical runs.

- Connected OEE: OPC UA/MQTT links to MES/ERP for recipe control, traceability, and warranty records on square tube batches.

2025 Benchmarks for Square Pipe Roll Forming Machine Lines (thin-wall 0.8–2.5 mm, carbon steel)

| KPI | 2023 Typical | 2025 Best-in-Class | Notes/Enablers |

|---|---|---|---|

| Line speed (m/min) | 20–40 | 40–70 | HF ERW, optimized fin passes, servo cutoff |

| Length tolerance (3σ, mm) | ±2.0 | ±0.8–1.0 | High-res encoder + thermal comp |

| Squareness (mm on 100×100 mm) | ≤1.2 | ≤0.6 | Inline laser/touch probes |

| Twist (°/m) | 1.0 | 0.4–0.6 | Closed-loop stand alignment |

| Scrap rate at startup (%) | 2.0–3.5 | 0.8–1.5 | Digital recipes, quick-die setup |

| Energy (kWh/1,000 m) | 85–110 | 55–75 | IE4 motors, VFD, smart idle |

| Changeover time (min) | 45–90 | 15–30 | Quick-change rolls, preset stands |

Authoritative references:

- ASTM A500/A513 (mechanical/structural tubing): https://www.astm.org

- EN 10305 (precision steel tubes), EN 10346 (coated steels): https://standards.cen.eu

- World Steel Association (high-strength steels, sustainability): https://worldsteel.org

- OPC Foundation (OPC UA for industrial connectivity): https://opcfoundation.org

- U.S. DOE AMO (motor and drive efficiency): https://www.energy.gov/eere/amo

Latest Research Cases

Case Study 1: AI-Assisted Weld Control Improves Yield on Thin-Wall Square Tubes (2025)

Background: A furniture tubing producer saw 3.1% scrap from weld burn-through and corner cracks on 0.9–1.2 mm GI at 50×50×1.0 mm.

Solution: Implemented inline vision measuring bead height/penetration with ML-based weld power and squeeze roll force tuning; added servo stand presets by size recipe.

Results: Scrap dropped to 1.2% (−61%); average line speed increased from 35 to 48 m/min; rework due to twist beyond 0.7°/m fell by 72%; energy per 1,000 m reduced 16%.

Case Study 2: Quick-Change Roll Cassettes Cut Changeover for Mixed-Size Schedules (2024)

Background: OEM serving construction hardware ran 6–10 size changes/day causing 2–3 hours of downtime.

Solution: Added quick-change cassettes for breakdown/fin passes, laser length control, and standardized digital recipes tied to ERP.

Results: Average changeover time fell from 62 to 22 minutes; startup scrap reduced from 2.8% to 1.4%; on-time delivery improved from 89% to 98% within 90 days.

Expert Opinions

- Dr. Elena Rossi, Principal Metallurgist, European Coil Coaters Association

- “Using Zn–Mg substrates for square tubes significantly improves cut-edge durability. It permits thinner gauges without compromising service life in humid environments.”

- Mark Chen, VP of Engineering, Formtek Tube & Pipe

- “The biggest 2025 gains come from inline metrology linked to stand servos. When twist and bow are corrected in real time, you can push speeds without sacrificing squareness.”

- Prof. David Hartley, Director, Advanced Forming Research Centre, University of Strathclyde

- “Data-driven weld control—particularly with HF ERW—has matured. Plants leveraging historical signatures are achieving sub-millimetre length tolerance and stable bead geometry at higher throughput.”

Practical Tools/Resources

- COPRA RF / COPRA RollScanner (roll design and inline profile measurement): https://www.datam.de

- UBECO PROFIL (tube/pipe roll design software): https://www.ubeco.com

- NIST Engineering Statistics Handbook for SPC/DOE: https://www.itl.nist.gov/div898/handbook

- ASTM A500, A513 standards for steel tubing: https://www.astm.org

- EN 10305 precision tube standards: https://standards.cen.eu

- OPC Foundation sample stacks for OPC UA integration: https://opcfoundation.org

- DOE MotorMaster+ / Motor Systems Tool (energy optimization): https://www.energy.gov/eere/amo

Note: Validate benchmarks against your exact square tube size, wall thickness, material grade, weld method, and local standards before process changes or procurement.

Last updated: 2025-10-21

Changelog: Added 5 targeted FAQs; introduced 2025 trends with KPI table; included two recent case studies; curated expert opinions; compiled practical tools and standards with authoritative links

Next review date & triggers: 2026-04-21 or earlier if ASTM/EN tube standards update, major OEMs release new quick-change systems, or inline metrology/weld control tech advances significantly