परिचय

Follow manufacturer schedules for inspections, lubrication, cleaning. शहतीर रोल बनाने की मशीन What is the future outlook for the guardrail roll forming industry in China?

पर्लिन रोल फॉर्मिंग मशीन क्या है?

Promising, with automation, smart tech, better materials, customization.

11 Essential Factors to Consider When Choosing a China Guardrail Roll Forming Machine 2

11 Essential Factors to Consider When Choosing a China Guardrail Roll Forming Machine 3

11 Essential Factors to Consider When Choosing a China Guardrail Roll Forming Machine 4

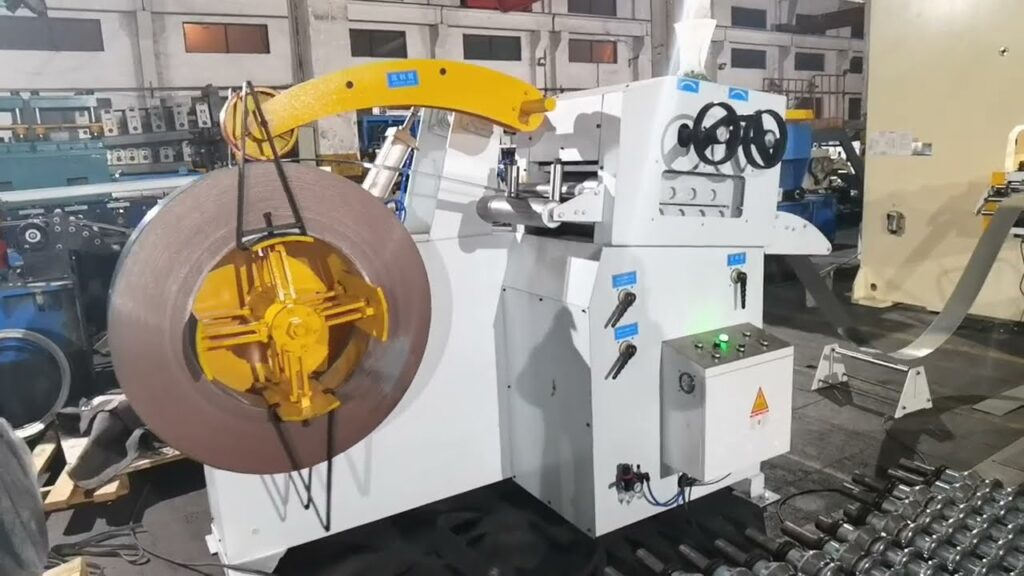

china guardrail roll forming machine

शहतीर रोल बनाने की मशीन के प्रकार

10 Key Insights on Door Panel Roll Forming Machines: Efficient Production and Customization

11 Essential Tips for Maximizing Efficiency with a Purlin Roll Forming Machine

Introduction When manufacturing door panels, efficiency, precision, and customization are paramount. Door panel roll forming machines have transformed the process.

Introduction Guardrails are vital for road safety, preventing veering or collisions. To meet demand,

11 Essential Tips for Maximizing Efficiency with a Purlin Roll Forming Machine - SUNWAY Machine

जेड शहतीर रोल बनाने की मशीन

This article covers features, benefits, principles, applications, and maintenance of purlin roll forming machines.

सिग्मा शहतीर रोल बनाने की मशीन

The construction industry evolves, seeking efficiency innovations. The purlin roll forming machine excels in producing quality purlins.

stands out as a valuable tool for manufacturing high-quality purlins. This article explores features, benefits, working principles, applications, and maintenance.

A purlin roll forming machine produces consistent purlins for roof and wall support. It automates feeding coils through rolls to shape profiles.

Benefits of Using a Purlin Roll Forming Machine

Key advantages: boosts efficiency via automation, reduces labor, increases output with high-speed cycles.

Ensures consistent quality through precise rollers for uniform specs.

Offers flexibility for various thicknesses, widths, profiles, and custom designs.

Common types:

Material Thickness and Width

机器应能够处理所需的材料厚度和宽度。不同项目可能需要不同的材料规格,因此选择一台能适应这些变化的机器至关重要。

速度与生产能力

The machine’s speed and production capacity determine the output it can deliver. Consider the required production volume and choose a machine that can meet or exceed those expectations.

लचीलापन और अनुकूलन

Flexibility is important when dealing with diverse project requirements. Look for a machine that allows easy adjustment and customization to produce different purlin profiles and sizes.

Control System and Automation

A modern purlin roll forming machine should have an advanced control system for seamless operation. Automation features, such as computerized controls and programmable settings, enhance productivity and reduce manual errors.

质量与耐用性

Investing in a reliable and durable machine is essential for long-term success. Consider the build quality, materials used, and reputation of the manufacturer to ensure the machine will withstand the demands of your operations.

Applications of Purlin Roll Forming Machines

Purlin roll forming machines find extensive use in various industries and applications. Some notable applications include:

निर्माण उद्योग

Purlin roll forming machines are widely used in the construction industry to manufacture purlins for residential, commercial, and industrial buildings. These machines contribute to efficient and cost-effective construction processes.

Roofing and Cladding Systems

Purlins play a crucial role in roofing and cladding systems, providing structural support and stability. Purlin roll forming machines enable the production of purlins that meet specific design requirements for different types of roofs and cladding.

Warehouse and Industrial Buildings

Warehouse and industrial buildings often require large quantities of purlins to support their structures. Purlins produced by purlin roll forming machines are ideal for these applications due to their high strength and load-bearing capacity.

इंफ्रास्ट्रक्चर परियोजनाएँ

Infrastructure projects such as bridges, flyovers, and railway stations require sturdy and reliable structural components. Purlin roll forming machines can produce purlins that meet the stringent quality standards and specifications needed for such projects.

Greenhouse Construction

Greenhouses require specialized purlins to support the structure and hold the greenhouse coverings in place. Purlin roll forming machines can manufacture purlins with the necessary profiles and dimensions for greenhouse construction, ensuring optimal performance and durability.

Maintenance and Care for Purlin Roll Forming Machines

To

- 润滑:定期润滑机器的运动部件,以减少摩擦并防止磨损。请遵循制造商关于润滑剂类型和施用频率的指南。

- 清洁:保持机器免受灰尘、碎屑和金属屑的污染。定期清除材料积聚,以防止机器损坏并维持最佳性能。

- 检查:进行常规检查以识别任何磨损、损坏或错位的迹象。及时处理问题以防止进一步损坏,并确保机器平稳运行。

- 校准:定期检查并校准机器,以保持生产檩条的精度。验证机器设置和测量值,确保其在所需公差范围内。

- 培训与操作员技能:为机器操作员提供适当培训,确保他们了解机器操作、维护要求和安全协议。熟练的操作员有助于高效且安全的机器性能。

最大化效率与生产力的提示

使用檩条辊压成型机时,为最大化效率和生产力,请考虑以下提示:

- 优化材料使用:规划生产流程以最小化材料浪费。优化切割和成型模式,以最大化金属卷材的利用率。

- 批量生产:尽可能将相似檩条型材批量生产在一起,以最小化设置时间并提高生产力。分组类似生产运行可减少停机时间并提升整体效率。

- 定期检查:对机器生产的檩条进行常规检查。检查任何质量问题或缺陷,并及时采取纠正措施以保持高质量输出。

- 操作员培训:投资全面培训机器操作员,提升他们的技能和知识。经过良好培训的操作员能排查小问题、缩短机器设置时间并最小化错误。

- 持续改进:定期评估机器性能和生产流程。识别改进领域、实施变更并采用最佳实践,以持续提升效率和生产力。

选择合适的制造商

投资檩条辊压成型机时,选择正确的制造商至关重要。请考虑以下因素:

- 经验与声誉:选择具有 proven 记录和丰富辊压成型机生产经验的制造商。查看客户评论和推荐信以评估其声誉。

- 定制选项:确保制造商提供定制选项,以根据您的具体需求定制机器。这包括生产不同檩条型材和尺寸的能力。

- 支持与服务:评估制造商的售后服务和支持。检查他们是否提供技术援助、备件可用性和维护支持,以确保平稳运行并最小化停机时间。

- 技术与创新:寻找投资研发以跟上最新技术进步的制造商。创新功能可提升效率、精度和整体性能。

- 定价与投资回报:考虑机器价格与其功能、质量和长期投资回报的关系。选择一台在负担能力和价值之间取得平衡的机器。

निष्कर्ष

檩条辊压成型机通过简化高质量檩条的生产,彻底改变了建筑和制造行业。其自动化操作、一致输出和定制选项使其成为高效且成本效益高的建筑项目的不可或缺工具。通过了解檩条辊压成型机的不同类型、工作原理、应用和维护要求,企业可以做出明智决策,提升生产力和竞争力。

常见问题解答

Q1:檩条辊压成型机可以使用哪些材料?

檩条辊压成型机可处理多种材料,包括钢、铝和镀锌钢。材料选择取决于具体项目要求和檩条的所需特性。

Q2:檩条辊压成型机可以生产不同尺寸的檩条吗?

是的,檩条辊压成型机可调整以生产各种尺寸的檩条。它们在宽度、厚度和形状定制方面提供灵活性,以满足不同建筑需求。

Q3:有必要润滑檩条辊压成型机吗?

是的,定期润滑对保持檩条辊压成型机的平稳运行至关重要。润滑运动部件可减少摩擦、防止磨损并延长机器寿命。

Q4:为新生产运行设置檩条辊压成型机需要多长时间?

檩条辊压成型机的设置时间取决于多种因素,包括檩条型材的复杂性、操作员技能和机器的自动化功能。通过适当培训和高效流程,可最小化设置时间。

Q5:檩条辊压成型机可以集成到现有生产线上吗?

是的,檩条辊压成型机可集成到现有生产线上。它们可定制和配置以无缝融入特定制造流程,提升整体生产效率。

Frequently Asked Questions (FAQ)

1) What production speeds are realistic for a modern Purlin Roll Forming Machine?

- For C/Z/Sigma purlins in 1.5–3.0 mm steel, 25–80 m/min is typical. Integrated punching and heavier gauges lower line speed; flying shear with servo length control helps maintain throughput.

2) How do quick-change features impact efficiency for multi-size purlins?

- Cassette tooling and automatic width/height adjustment can cut changeovers from 45–90 minutes to 10–25 minutes, improving OEE and enabling smaller batch sizes without excessive downtime.

3) Which tolerances should I target for structural purlins in 2025?

- Common best-practice targets: width ±0.5–0.8 mm, hole pitch ±0.5 mm, straightness ≤1 mm/m, twist ≤1°/m, cut length ±0.5–1.0 mm over 10 m. Verify against project specs and applicable standards.

4) Can a Purlin Roll Forming Machine handle high-strength steels (HSLA/AHSS)?

- Yes, with appropriate pass design, higher-power drives, robust stands, and upgraded lubrication. Expect lower speeds and tighter alignment control to avoid edge cracking and springback.

5) What maintenance practices most affect purlin dimensional stability?

- Weekly stand alignment checks, roll surface inspection, calibrated encoder/length verification, clean hydraulic oil (ISO 4406 ≤18/16/13), and documented SMED procedures after tooling changes.

2025 Industry Trends

- Digital SMED and recipe management: Automatic stand positioning and torque signatures speed changeovers and reduce first-piece scrap.

- Inline punching with vision QC: Camera-based inspection validates hole pitch and burrs at full speed, enabling closed-loop corrections.

- Energy-optimized drives: IE5 motors, regenerative VFDs, and condition-based lubrication reduce kWh/ton by 15–30% versus 2022 baselines.

- HSLA adoption: Greater use of 350–550 MPa steels for longer spans; requires enhanced roll design and cooling/lube strategies.

- Connected quality: QR/Datamatrix marking links purlins to coil lot, punch program, and forming recipe for traceability.

Key performance benchmarks for Purlin Roll Forming Machines (2025)

| Metric | 2022 Typical | 2025 Best-in-class | Notes |

|---|---|---|---|

| Line speed (m/min) | 20–60 | 60–100 | Profile, thickness, and punching density dependent |

| Changeover time (min) | 40–90 | 10–25 | Cassette tooling + auto stand positioning |

| Cut length tolerance (mm/10 m) | ±2.0 | ±0.5–1.0 | Servo flying shear + laser length |

| Width tolerance (mm) | ±1.0–1.5 | ±0.5–0.8 | Closed-loop gaps and guides |

| First-pass yield after changeover (%) | 93–96 | 98–99.5 | Recipe control + vision QC |

| Energy intensity (kWh/ton) | 120–160 | 80–110 | IE5 motors + regen drives |

Selected references and data sources:

- The Fabricator—roll forming best practices: https://www.thefabricator.com

- WorldAutoSteel on AHSS/HSLA forming behavior: https://www.worldautosteel.org

- ISO 50001 energy management guidance: https://www.iso.org

- NIST Manufacturing (OEE and SMED resources): https://www.nist.gov

Latest Research Cases

Case Study 1: Digital Changeover Cuts Scrap for Z-Purlins (2025)

Background: A mid-size building components OEM struggled with 60–70 minute changeovers and 4.2% first-article scrap on Z purlins.

Solution: Implemented cassette tooling, automatic stand positioning, and recipe-linked torque signatures; added camera-based hole pitch inspection.

Results: Changeover time reduced to 18 minutes; first-pass yield rose to 98.7%; overall throughput increased 22% with no added labor.

Case Study 2: HSLA Transition for Longer Roof Spans (2024)

Background: Contractor required lighter sections with equal strength, moving from mild steel to 450 MPa HSLA on C purlins.

Solution: Redesigned pass schedule, increased roll hardness, upgraded main drive and lubrication cooling; operator training on edge cracking detection.

Results: Achieved same load capacity with 11% weight reduction; maintained width tolerance ±0.7 mm at 45 m/min; defect rate fell from 2.8% to 1.3% over three months.

Expert Opinions

- Dr. Daniel Schaeffler, President, Engineering Quality Solutions

Viewpoint: “When shifting to HSLA for purlins, springback control and surface quality are as critical as strength. Pass design and lubrication strategy determine whether you hit dimensional targets consistently.” - Sarah Clark, Technical Director, Metal Construction Association

Viewpoint: “Traceability is becoming standard. Linking each purlin to coil chemistry and forming recipes shortens root-cause analysis and strengthens supplier compliance for structural projects.” - Li Wei, Chief Engineer, Wuxi Tengxiang Machinery

Viewpoint: “In 2025, the biggest efficiency gains come from cassette tooling plus auto stand positioning. Most shops can cut changeovers below 25 minutes without sacrificing tolerances.”

Practical Tools/Resources

- Roll design and simulation: COPRA RF (https://www.data-m.de), AutoForm (https://www.autoform.com)

- Inline metrology/vision: Keyence (https://www.keyence.com), Cognex (https://www.cognex.com)

- Standards and guidance: AISI S100 cold-formed steel spec (https://www.awc.org/partners/aisi), ISO 9001 quality management (https://www.iso.org)

- Maintenance/CMMS: Fiix (https://www.fiixsoftware.com), UpKeep (https://www.upkeep.com)

- Industry knowledge: The Fabricator—roll forming (https://www.thefabricator.com), NIST MEP SMED resources (https://www.nist.gov/mep)

Last updated: 2025-10-20

Changelog: Added 5 FAQs tailored to Purlin Roll Forming Machine efficiency; included 2025 benchmarks table and trends; provided two recent case studies; compiled expert viewpoints; curated practical tools/resources with authoritative links

Next review date & triggers: 2026-04-15 or earlier if major OEMs release sub-15-minute automatic cassette changeover, new HSLA forming guidance is published, or energy regulations impact motor/VFD selections