परिचय

In manufacturing and construction, efficiency and precision matter. For metal studs, stud roll forming machine a stud roll forming machine is essential. This article explores its concept, benefits, features, types, applications, operations, safety, troubleshooting, and trends.

What is a Stud Roll Forming Machine?

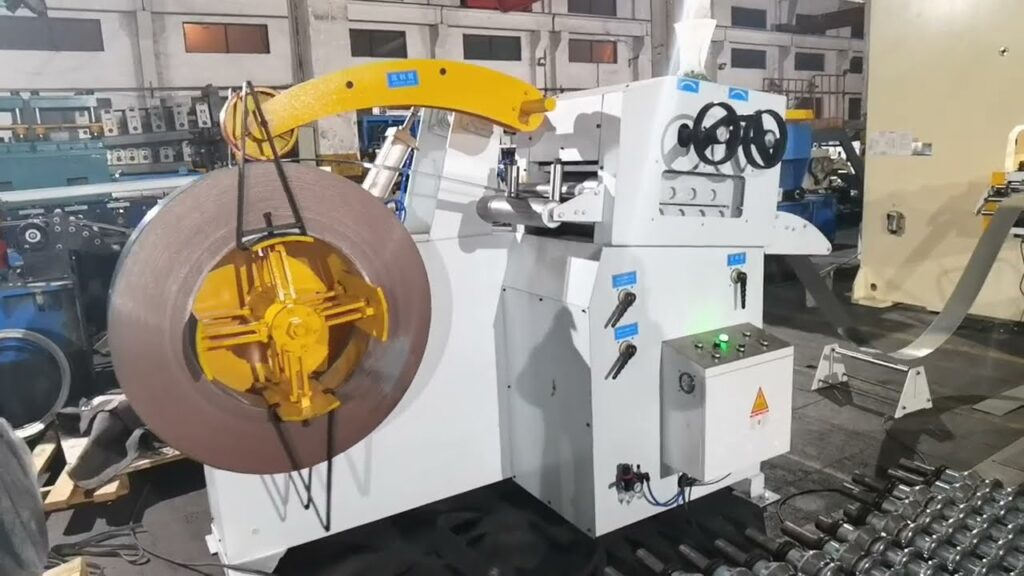

A stud roll forming machine produces metal studs or tracks with uniform shapes and dimensions via continuous bending of coils. Used in construction for walls, ceilings, and structures, it handles steel, aluminum, and galvanized steel.

Advantages of Using a Stud Roll Forming Machine

These machines outperform traditional methods:

- High EfficiencyHigh-speed operation boosts output over manual processes.

- Precision and ConsistencyThey deliver exact dimensions and uniform quality for better assembly.

- High speed for volume.Automation cuts labor and waste, saving costs.

- VersatilityVersatility for diverse stud profiles.

Key Features of a Stud Roll Forming Machine

Key features optimize production:

- 开卷机Decoiler feeds the metal coil.

- Roll Forming Stations: The machine consists of a series of roll forming stations where the metal undergoes sequential bending and shaping.

- Cut-off Mechanism: After forming the desired length of the stud, the machine employs a cut-off mechanism to separate it from the continuous coil.

- नियंत्रण प्रणाली: Modern stud roll forming machines incorporate advanced control systems to monitor and adjust various parameters, such as speed, length, and cut-off precision.

- Fitur Keselamatan: To ensure operator safety, these machines often include safety guards, emergency stop buttons, and interlock systems.

Types of Stud Roll Forming Machines

Stud roll forming machines come in different types, each designed to cater to specific production needs. The common types include:

Single-Sided Stud Roll Forming Machine

The single-sided stud roll forming machine produces

Double-Sided Stud Roll Forming Machine

Forms profiles on both sides for dual-function needs.

Track Roll Forming Machine

Creates tracks for ceilings, lighting, or partitions.

Applications of Stud Roll Forming Machines

Common uses:

- Framing for buildings

- Partition walls and ceilings

- Roofing and cladding

- Drywall assemblies

- Prefabricated structures

Factors to Consider When Choosing a Stud Roll Forming Machine

Key selection factors:

सामग्री संगतता

Material compatibility (steel, aluminum, galvanized).

उत्पादन गति

Production speed matching timelines.

定制选项

Adjustability for profiles.

मशीन की टिकाऊपन

Durable components.

Maintenance and Support

Availability of support and parts.

How to Operate a Stud Roll Forming Machine

Steps for safe operation:

- SetupLoad coil and adjust stations.

- FeedingEnsure smooth feed with tension.

- FormingSequential bending through stations.

- Cut-offSeparate at length.

- Collecting and StackingSecure finished products.

Safety Measures for Using a Stud Roll Forming Machine

Prioritize safety:

- Wear PPE (glasses, gloves, ear protection).

- Know safety features and stops.

- Inspect and replace parts regularly.

- Train and supervise operators.

Troubleshooting Common Issues with Stud Roll Forming Machines

Stud roll forming machines may encounter occasional issues during operation. Here are some common problems and their possible solutions:

- सामग्री जाम होना: Clear any debris or metal pieces that may cause the material to get stuck in the machine.

- Inconsistent Dimensions: Check and adjust the roll forming stations to ensure proper alignment and bending angles.

- Cut-off Errors: Verify the cut-off mechanism settings and adjust the blade position or replace any dull blades.

- Irregular SpeedInspect the motor and drive systems for any malfunctions or misalignments that may affect the machine's speed.

If the troubleshooting steps do not resolve the issues, it is recommended to consult the machine's manual or contact the manufacturer for further assistance.

Future Trends in Stud Roll Forming Machine Technology

The field of stud roll forming machines continues to evolve, with advancements in technology shaping the future of this industry. Here are some emerging trends to watch for:

- Automation and RoboticsIncreasing automation and integration of robotics into stud roll forming machines will enhance production efficiency and reduce the need for manual intervention.

- Smart ManufacturingIntegration of sensors and data analytics will enable real-time monitoring of machine performance, predictive maintenance, and optimization of production processes.

- 能效高Manufacturers are focusing on developing energy-efficient stud roll forming machines by employing advanced motor and drive systems, reducing overall energy consumption.

- Enhanced CustomizationFuture machines will offer even greater flexibility in producing customized stud profiles to meet specific project requirements.

- Improved Safety FeaturesOngoing research and development will lead to the implementation of advanced safety features, ensuring the highest levels of operator safety during machine operation.

निष्कर्ष

Stud roll forming machines have revolutionized the production of metal studs and tracks, offering high efficiency, precision, and versatility. By automating the manufacturing process, these machines enable cost-effective production while maintaining consistent quality. When selecting a stud roll forming machine, factors such as material compatibility, production speed, customization options, machine durability, and maintenance support should be considered. Operating the machine safely and following troubleshooting techniques for common issues ensures smooth production. As the industry continues to advance, the future holds exciting possibilities with automation, smart manufacturing, and improved customization in stud roll forming machine technology.

常见问题解答

Q1. Are stud roll forming machines only used in the construction industry?

No, stud roll forming machines are also used in various manufacturing industries where metal studs or tracks are required, such as automotive, aerospace, and appliance manufacturing.

Q2. Can stud roll forming machines produce different sizes of studs?

Yes, stud roll forming machines can be adjusted to produce studs of various lengths and widths, allowing for customization based on project requirements.

Q3. Are stud roll forming machines difficult to operate?

While operating a stud roll forming machine requires proper training and knowledge, modern machines often come with user-friendly interfaces and control systems, making them relatively easy to operate.

Q4. How long does it take to set up a stud roll forming machine for a new profile?

The setup time for a new profile can vary depending on the complexity of the profile and the operator's experience. Generally, it can take anywhere from a few minutes to an hour to set up the machine for a new profile.

Q5. Can stud roll forming machines work with different types of metal materials?

Yes, stud roll forming machines can work with various metal materials, including steel, aluminum, and galvanized steel. However, it is essential to ensure the machine is compatible with the specific material you intend to use.