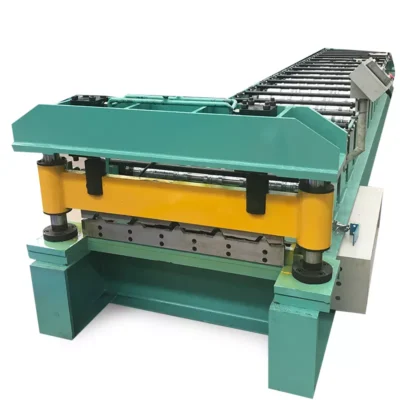

Standing Seam Roof Panel Forming Machine Features:

This standing seam roof panel forming machine processes pre-painted sheet, GI/GA, and aluminum materials. It consists of an uncoiler, guide feeder, roll forming machine, hydraulic cutting machine, PLC control system, hydraulic station, output tables, auto seamer, and curving machine (optional).

अनुप्रयोग

तैयार उत्पादों का उपयोग जिमनेजियम, हवाई अड्डों, थिएटरों, कारखानों, गोदामों, गैरेज, प्रदर्शनी केंद्रों आदि की छत और दीवारों के रूप में किया जाता है।

प्रक्रिया प्रवाह

Uncoiling — Feeding — Roll Forming — Cutting — Output — Seaming — Curving (optional)

मशीन विन्यास

| 1. Uncoiler |

2. Guide Feeder

|

| 3. Roll Former |

4. Hydraulic Cutting Machine

|

| 5. PLC Control System |

6. हाइड्रोलिक स्टेशन

|

| 7. आउटपुट कन्वेयर |

8. ऑटो सीमर

|

| 9. Curving Machine (Optional) |

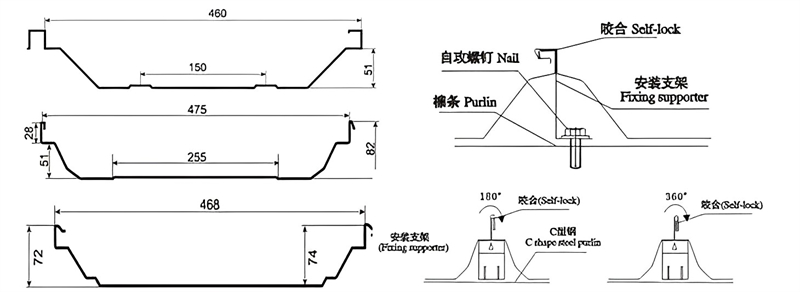

संदर्भ के लिए प्रोफाइल ड्राइंग्स

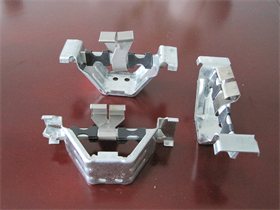

संदर्भ के लिए फोटो

What Is a Standing Seam Roll Forming Machine?

A standing seam roll forming machine is specialized construction equipment for producing standing seam metal roof panels. Renowned for durability, weather resistance, and aesthetics, these roofs feature vertical panels joined by interlocking seams for watertight security.

The machine converts flat metal coils into standing seam profiles via sequential rollers and dies in a continuous process, feeding coils and cutting panels to length.

Key features include:

- Entry section: Introduces the flat coil for processing.

- Rollers and dies: Gradually shape the coil into the seam profile.

- Panel cutting system: Trims formed panels to length.

- Control system: Sets dimensions, profiles, and cuts via panel interface.

- Material handling: Manages coil loading, guiding, and support.

This machine enables custom-length panels with uniformity, slashing labor and boosting efficiency over manual methods.

How to Use a Standing Seam Roof Panel Roll Forming Machine?

Operation typically follows these steps:

- Set up the machine: Install securely with safety features engaged.

- Prepare the coil: Load and align on the holder.

- Adjust settings: Configure width, profile, and length per manual.

- Start operation: Feed coil; rollers form the profile.

- Monitor: Watch for issues like misalignment.

- Cut panels: Ensure accurate trimming.

- Collect: Stack finished panels safely.

- Repeat: Process additional coils, addressing issues promptly.

Procedures vary by model; consult manuals and training for safety and efficiency.

Applications of Snap Lock Standing Seam Roll Forming Machines

These machines produce snap lock standing seam roof panels, where panels interlock without fasteners for secure, watertight joints.

Primarily for residential, commercial, and industrial roofing, key uses include:

- Roofing: Sleek, durable solutions for diverse buildings.

- Residential: Enhances homes with lasting protection and appeal.

- Commercial/industrial: Withstands demanding environments in warehouses and offices.

- Architectural: Complements modern designs.

- Retrofitting: Upgrades existing roofs for better performance.

The machine ensures precise, efficient production for construction demands.

समीक्षा

अभी तक कोई समीक्षा नहीं।