Scaffolding Walk Board Roll Forming Machine Features:

Metaldeck scaffolding represents a revolutionary metal decking access platform for tubular scaffolds. Since its introduction, it has earned a reputation for reliable and safe performance. This strong yet lightweight galvanized metal scaffold deck is now widely used throughout the industry as a replacement for conventional timber.

The METALDECK is positioned on the scaffolding to bridge its frames and create a horizontal work platform. During installation on the scaffolding frame, each METALDECK must be “secured” at the bottom with a specific safety pin to ensure safe placement and prevent accidental dislodgement.

The Metaldeck Scaffolding Roll Forming Machine consists of a decoiler, guide rack, leveler, flattener, continuous punching machine, roll forming unit, correction device, cut-to-length (punching) system, collection table, electrical control system, and more.

अनुप्रयोग

Metaldeck scaffolding is widely used on construction sites.

प्रक्रिया प्रवाह

Decoiling — Leveling — Punching — Roll Forming — Cutting — Runout Table

मशीन विन्यास

| 1. Hydraulic Uncoiler | 2. Side Guide |

| 3. Leveling Device |

4. Continuous Punching Unit

|

| 5. Roll Forming Unit |

6. Cutting Device

|

| 7. Runout Table |

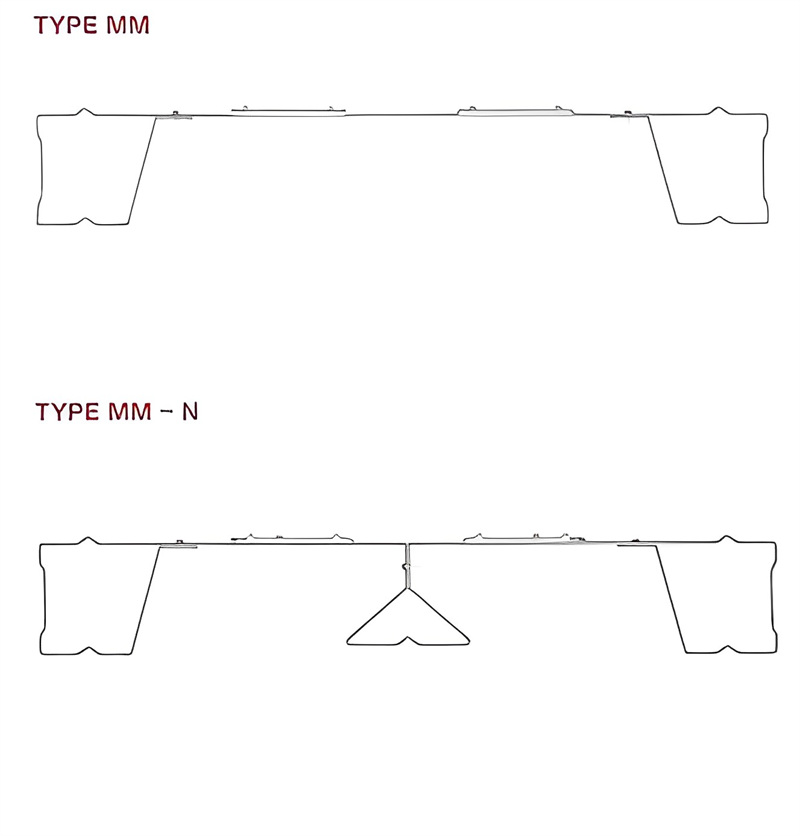

संदर्भ के लिए प्रोफाइल ड्राइंग्स

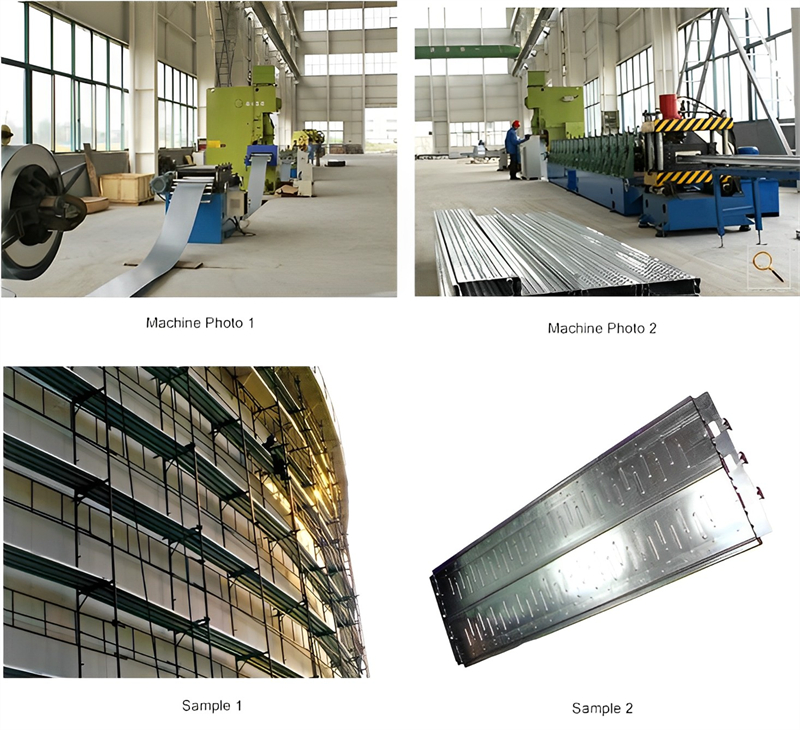

संदर्भ के लिए फोटो

什么是车厢板辊压成型机?

车厢板辊压成型机是一种工业机械,通过辊压成型工艺制造车厢板。

车厢板是细长平坦的板材,通常用于建筑行业,用于外墙板、隔墙或装饰元素等各种用途。通常由金属或塑料等材料制成。

辊压成型机专为生产车厢板而设计,由一系列依次排列的辊轮和模具组成。原材料如金属卷材或塑料板材被送入机器,随着其通过辊轮,经历一系列弯曲、成型和切割操作。

The rollers and dies in the machine are strategically positioned to gradually shape the material into the desired profile. Each set of rollers handles a specific section of the carriage board, such as corrugations or decorative patterns. The material feeds continuously through the machine, undergoing sequential operations until it reaches the end of the production line.

The carriage board roll forming machine is typically fully automated and features advanced control systems to guarantee precision and uniformity throughout the manufacturing process. It enables high-volume production at rapid speeds, providing an efficient solution for mass manufacturing.

In summary, the carriage board roll forming machine is specialized equipment in the construction sector, designed to create carriage boards with precise profiles and dimensions, delivering a cost-effective and streamlined manufacturing approach.

What are the main applications of sheet metal roll forming machines?

Sheet metal roll forming machines serve a broad array of applications across multiple industries. Key uses include:

- Construction and Architecture: These machines are widely employed in construction to produce roofing sheets, wall panels, cladding systems, gutters, and other structural elements. They generate profiles in varied shapes, sizes, and finishes, offering flexible solutions for architectural designs.

- Automotive Industry: In the automotive sector, roll forming machines are vital for creating components such as door frames, window channels, roof rails, bumper beams, and other structural parts. They process high-strength materials into intricate profiles essential for vehicle body frames and chassis.

- HVAC (Heating, Ventilation, and Air Conditioning): Roll forming machines in the HVAC field manufacture ductwork, ventilation pipes, air diffusers, and related components. They deliver precise profiles with uniform dimensions, promoting optimal airflow and reliable system performance.

- Furniture Manufacturing: These machines support furniture production by forming metal components for bed frames, shelves, table legs, and structural elements. They allow for tailored profiles to satisfy unique design specifications.

- Electrical Enclosures and Panels: Roll forming machines produce electrical enclosures, control panels, switchgear cabinets, and housings for electrical equipment. They shape sheet metal into exact profiles, incorporating slots, holes, and features for mounting components and routing wiring.

- Shelving and Racking Systems: Employed in shelving, racking, and storage solutions, these machines create profiles for shelves, beams, uprights, and components. This facilitates efficient storage and organization in warehouses, retail environments, and industrial facilities.

- Solar Energy Industry: In solar applications, the machines fabricate mounting structures and frames for panels. They produce robust, durable profiles resilient to environmental stresses, ensuring stability for solar systems.

These represent only a selection of applications for sheet metal roll forming machines. Their adaptability, efficiency, and capacity for consistent, high-quality profiles render them indispensable across industries.

Functions of the Metal Deck Roll Forming Machine

A metal deck roll forming machine is engineered specifically to produce metal deck sheets, which serve as structural elements in composite floor systems within construction. It executes multiple functions to convert raw materials into finished sheets:

- Uncoiling: Equipped with an uncoiler, the machine unwinds the metal coil and introduces it into the production line, ensuring a steady material supply.

- Material Feeding: The machine advances the coil through rollers and guides, maintaining precise alignment and positioning during forming.

- Roll Forming: At its core, the machine progressively shapes the coil into the metal deck profile using paired rollers and dies. These components methodically bend, form, and emboss the material, incorporating features like stiffening ribs and interlocking mechanisms.

- Cutting: Upon reaching the specified length, a cutting mechanism—such as a flying cutoff or stationary shear—trims the sheet accurately.

- Stacking or Discharging: Post-cutting, a stacking system organizes the sheets for handling and transport, or they are discharged via conveyor.

- Forming Variations: These machines accommodate diverse profiles and sizes by adjusting rollers, dies, and cutters, enabling production flexibility.

Overall, the metal deck roll forming machine integrates uncoiling, feeding, forming, cutting, and stacking to efficiently manufacture sheets for composite floors. It ensures precise, consistent output, yielding reliable structural components for construction.

समीक्षा

अभी तक कोई समीक्षा नहीं।