विशेषताएँ

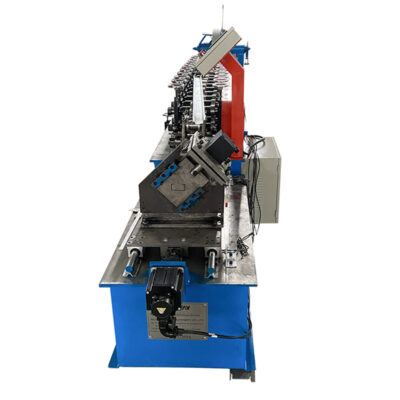

The hollow guide rail production line is designed for manufacturing various elevator hollow guide rails with wall thicknesses of 2.3 mm to 3.2 mm. This innovative production line offers advantages such as high precision and rapid processing speeds, which can be several times faster than traditional lines.

अनुप्रयोग

Finished products are widely used in elevators and similar applications.

प्रक्रिया प्रवाह

Uncoiler — Shear & Butt Welder — Accumulator — Leveling — Roll Forming — Flying Cutting — Runout Table

मशीन विन्यास

| 1. Double-Head Uncoiler |

2. Shear & Butt Welder

|

| 3. Horizontal Accumulator | 4. Leveling |

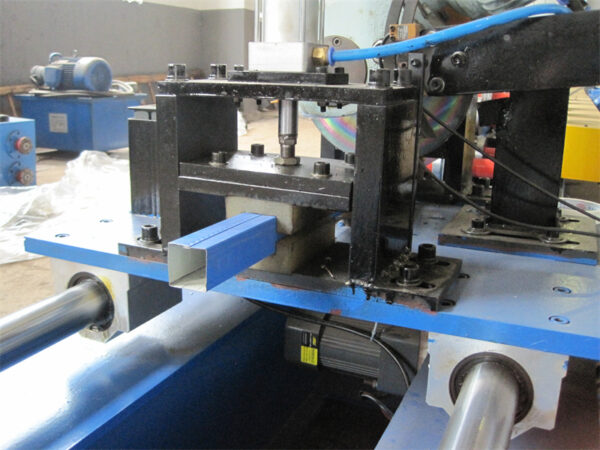

| 5. रोल बनाने की मशीन | 6. Flying Cutting Device |

| 7. Runout Table |

What is the working principle of a guide rail roll forming machine?

Designed for producing guide rails (also known as guardrails or safety barriers), the machine operates through these steps:

- Material feeding: A steel or aluminum coil is loaded onto a decoiler and fed into the machine via entry rollers.

- Roll forming: The material advances through sequential roller stations, each progressively shaping it into the target guide rail profile via controlled pressure and bending.

- Cutting: A cutting mechanism—such as flying cutoff or hydraulic shearing—severs the formed profile into specified lengths.

- Forming and finishing: Optional processes like punching, embossing, or surface treatments (e.g., galvanizing or painting) enhance strength, functionality, or corrosion resistance.

- Stacking or packaging: Finished sections are stacked for processing or packaged for shipment.

Precise control of rollers, cutters, and components ensures accurate profiles. The control system synchronizes operations based on specifications for efficient, high-precision production.

Applications of DIN rail roll forming machines

DIN rail roll forming machines produce standardized metal rails for electrical and electronic installations, serving industries such as:

- Electrical panel manufacturing: DIN rails mount components like circuit breakers, relays, terminal blocks, and power supplies in panels.

- Industrial automation: They organize PLCs, motor starters, contactors, and power modules in standardized setups.

- Building automation: Used for HVAC, lighting, security, and management systems.

- Renewable energy: Mount inverters, controllers, and monitors in solar and wind systems.

- Railway and transportation: Secure controls and equipment on trains and vehicles.

Overall, these machines support standardized mounting in electrical and electronic sectors, enabling efficient equipment organization.

What are the differences between slide rail and DIN rail roll forming machines?

Key differences include:

- Purpose: Slide rail machines produce rails for guiding and supporting movable objects in machinery, automation, and conveyors. DIN rail machines create rails for mounting electrical/electronic equipment.

- 形状与尺寸:滑轨通常具有U形或C形截面,可为单槽或多槽结构。其尺寸和形状可根据具体应用需求定制。而DIN导轨则遵循DIN标准,通常具有标准化的截面和尺寸,便于电气和电子设备的便捷安装和固定。

- 安装方式:滑轨通常使用螺栓、螺钉或其他紧固件安装,提供可调节或可移动的支持和引导。而DIN导轨则通常使用安装螺钉或其他紧固件直接固定在电气或电子设备的底座上。

- 制造工艺:滑轨辊压成型机与DIN导轨辊压成型机的制造工艺略有差异。滑轨辊压成型机使用一系列辊轮和切割装置,根据滑轨的形状和尺寸将连续卷材成型并切割成所需的滑轨型材。DIN导轨辊压成型机则遵循DIN标准,使用专用辊轮和切割装置将卷材成型并切割,以满足DIN导轨的标准要求。

总之,滑轨辊压成型机与DIN导轨辊压成型机服务于不同的应用和安装需求。滑轨用于引导和支撑物体运动,而DIN导轨用于电气和电子设备的安装与固定。它们在形状、尺寸和制造工艺上存在差异,以满足特定应用需求和标准要求。

समीक्षा

अभी तक कोई समीक्षा नहीं।