High-Speed C Purlin Machine Features

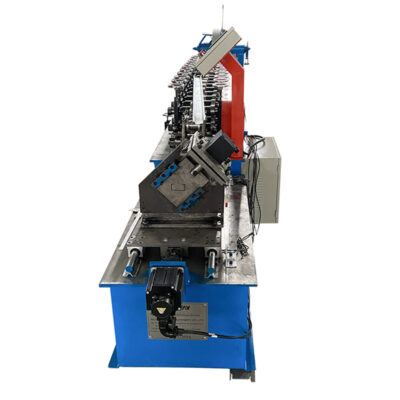

The high-speed C purlin machine is designed for high-volume production, with speeds exceeding 40 m/min.

अनुप्रयोग

Finished products are widely used in building construction and PV solar mounting brackets.

प्रक्रिया प्रवाह

Uncoiler — Accumulator — Butt Welding — Feeding — Straightening — Roll Forming — Cutting — Exit Rack

मशीन विन्यास

| 1. 3T × 500 मिमी हाइड्रोलिक अनकॉइलर | 2. Accumulator |

| 3. Butt Welding |

4. Feeding Device and Straightening

|

| 5. रोल बनाने की मशीन | 6. Servo Tracking Cutter |

| 7. पीएलसी नियंत्रण प्रणाली | 8. रैक से बाहर निकलें |

What Are the Components of a C Purlin Roll Forming Machine?

A C purlin roll forming machine comprises key components that shape metal strips into C purlins. Configurations vary by design and manufacturer, but typical elements include:

- Decoiler: Holds and unwinds the steel coil for controlled feeding into the forming process.

- Feeding System: Guides the metal strip from the decoiler to the forming section using rollers or similar mechanisms.

- Leveling System: Flattens the strip to ensure uniformity, removing curvature or distortions before roll forming.

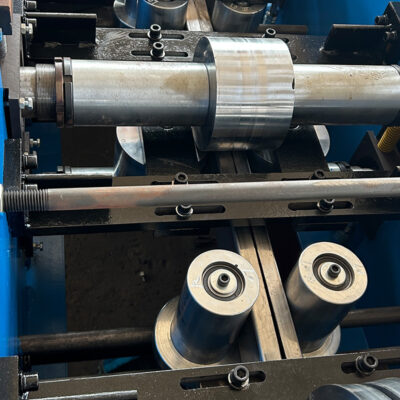

- Roll Forming Rollers: Sequenced rollers that progressively bend the strip into the C profile, each performing specific forming operations.

- Cutting System: Cuts the formed purlin to length using flying shear, hydraulic shear, or similar mechanisms.

- Control System: Electrical and electronic components, including PLC or computerized panels, for parameter setting and performance monitoring.

- Drive System: Powers rollers and moving parts via motors, gearboxes, chains, and belts.

- Support and Frame Structure: Provides stability, including guide rails, side frames, and supports for the formed purlins.

These are the primary components, with additional features possible based on design.

How Much Does a C Purlin Roll Forming Machine Cost?

Prices for C purlin roll forming machines vary widely based on specifications, quality, manufacturer, location, and features, making exact figures dependent on details.

Generally, they range from tens of thousands to hundreds of thousands of dollars. Basic models are more affordable, while high-capacity, advanced, or customized units cost more.

Consider total investment, including shipping, installation, training, maintenance, and support.

For precise quotes, contact manufacturers or suppliers directly, providing your requirements for tailored recommendations.

How Does OEM C Purlin Roll Forming Machine Collaboration Work?

OEM collaboration for C purlin roll forming machines involves partnering with a manufacturer to design, produce, and brand machines under your label or as custom solutions.

- Identifying the OEM Partner: Select a reputable manufacturer with expertise in C purlin machines.

- Requirement Analysis: Share specifications, performance needs, customizations, and branding guidelines.

- Design and Development: The partner engineers components like rollers, cutters, drives, and controls to meet your specs.

- Prototype and Testing: Produce and rigorously test a prototype for quality, performance, and compliance.

- Customization and Branding: Incorporate client-specific elements like logos, colors, or features.

- Production and Delivery: Manufacture agreed quantities and deliver to you or your network.

- Support and Service: Provide ongoing technical assistance, training, and maintenance.

OEM partnerships leverage manufacturer expertise for customized solutions, portfolio expansion, and market entry.

समीक्षा

अभी तक कोई समीक्षा नहीं।