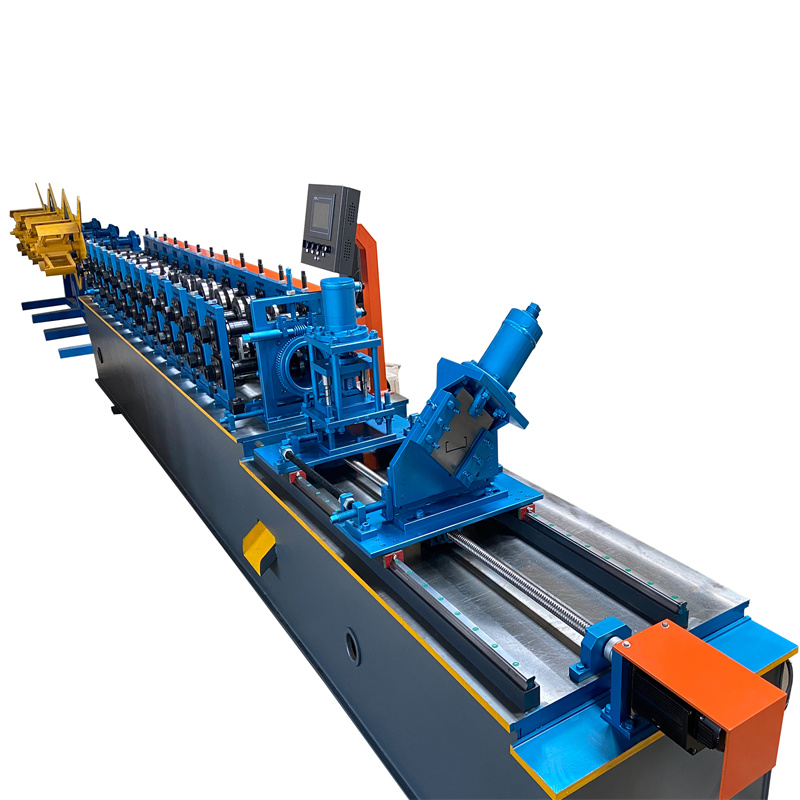

Keel/Truss/C/U/Omega/Stud Steel Roll Forming Machine with a small dimension, easy to transport. The speed can be up to 60m/min transmission, so the working will be more stable. We can also supply the customized machines.

C Channel Steel Roll Forming Machine Details

High Speed

Our high speed C/U/Omega stud roll forming machine speed can up to 60m/min. Normally, C//UOmega stud roll forming machine’s speed is around 45m/min

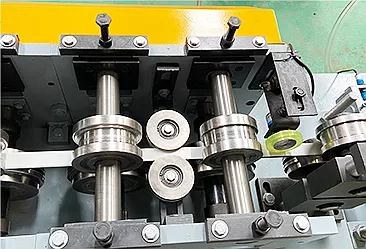

High speed C/U/Omega stud roll forming machine adopts cast steel roller fixer

High speed C/U/Omega stud roll forming machine adopts PLC system. Customer can set production quantity, production speed on control cabinet.

वरिष्ठ और अनुभवी इंजीनियर आपके अनुकूलित करने के लिए पूरी प्रक्रिया को नियंत्रित करते हैं।

C Channel Steel Roll Forming Machine Parameters

| Raw Material | Galvanized Sheet Or PPGI, PPGL |

| Thickness Of Sheet (mm) | Customized |

| Operation | Fully Automatic |

| Transmission | By Chain/Gear |

| रोलर सामग्री | Cr12 |

| Shaft Diameter | 50mm Or As Per Profile |

| रोलर स्टेशन | 10-16 Stations |

| Cutter | Hydraulic Servo Cutting With High Speed |

What is c channel roll forming machine?

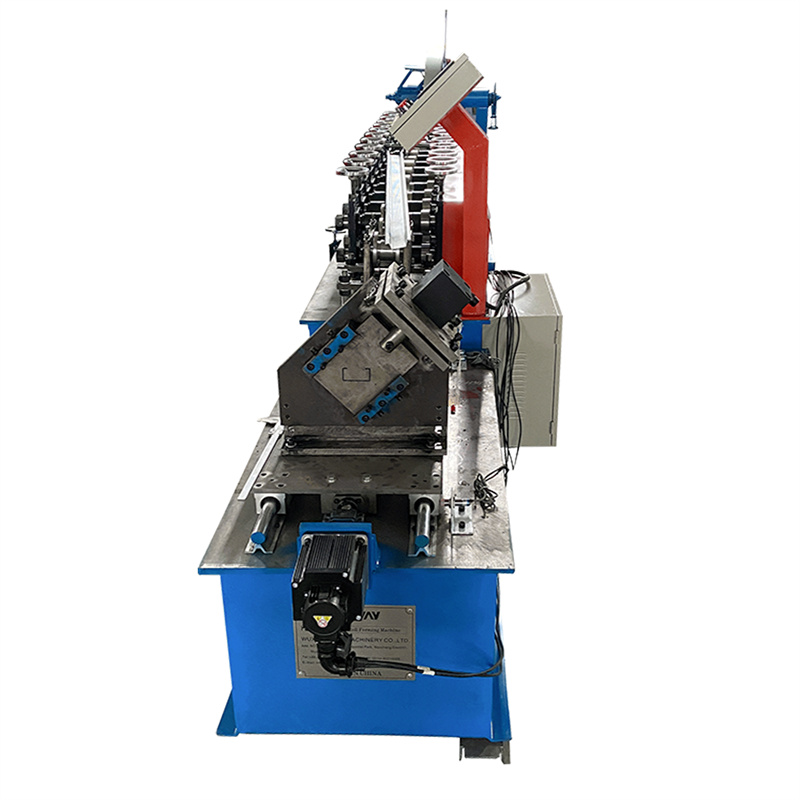

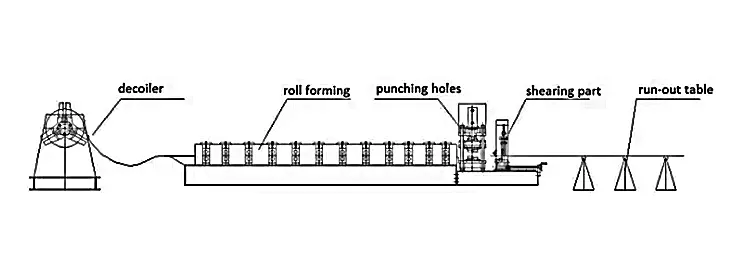

C-channel roll forming machine is a specialized piece of equipment used in the manufacturing industry to produce C-shaped steel channels through a process called roll forming. Roll forming is a continuous bending operation where a long strip of metal is passed through a series of roller dies, gradually shaping it into the desired profile.

The C-channel profile is commonly used in construction and structural applications, as it provides strength and stability while minimizing weight. It resembles the letter “C” when viewed in cross-section, with a flat back and two perpendicular flanges extending outward.

The roll forming machine for C-channels consists of a series of forming stations, each equipped with pairs of rollers that gradually shape the metal strip. These rollers are designed to produce the specific dimensions and features of the C-channel profile, such as the flange width, lip size, and overall dimensions. The machine may also include additional stations for cutting the formed channels to the required length.

C-channel roll forming machines are typically automated and can handle high-volume production. They offer precise control over the forming process, allowing manufacturers to consistently produce C-channels with accurate dimensions and high-quality finishes.

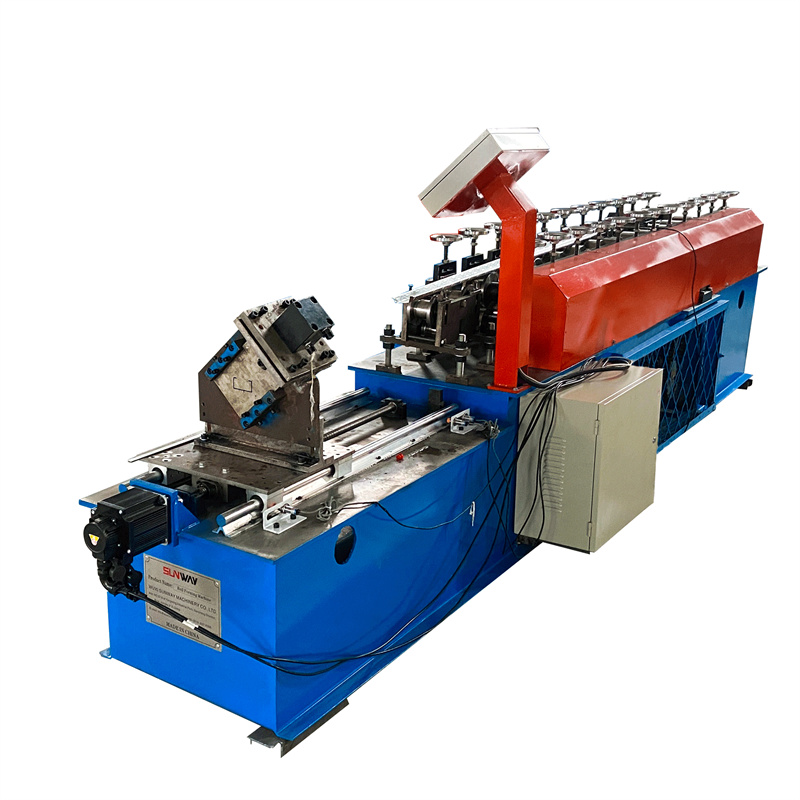

What is furring channel roll forming machine?

A furring channel roll forming machine is another type of specialized equipment used in the manufacturing industry. It is designed to produce furring channels through the process of roll forming. Furring channels are commonly used in construction for various applications such as creating suspended ceilings, partition walls, and attaching drywall.

Furring channels are typically made from galvanized steel or other metals and have a hat-shaped cross-section. They feature a flat base with two parallel legs or flanges extending upward. The legs have embossed or perforated patterns to provide strength and facilitate attachment to other building materials.

The furring channel roll forming machine consists of a series of forming stations, similar to the C-channel roll forming machine. These stations are equipped with roller dies that gradually shape the metal strip into the desired furring channel profile. The machine may also include additional stations for punching holes or embossing patterns onto the legs of the channel.

During the roll forming process, the metal strip is fed into the machine, and the rollers progressively bend and shape it into the furring channel profile. The formed channels can be cut to the desired length using a cutting station integrated into the machine or as a separate post-process.

Furring channel roll forming machines are designed for high-volume production, offering precise control over the dimensions and features of the channels. They enable manufacturers to produce furring channels with consistent quality, making them ideal for construction projects where accurate and standardized components are required.

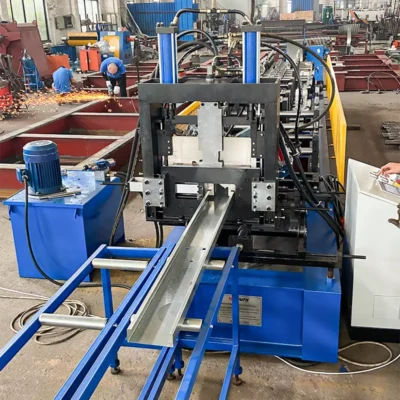

What is hat channel roll forming machine?

A hat channel roll forming machine is a specialized piece of equipment used in the manufacturing industry to produce hat channels through the process of roll forming. Hat channels, also known as furring channels or resilient channels, are commonly used in construction for applications such as attaching drywall, creating suspended ceilings, and providing structural support.

Hat channels have a distinctive “hat” or “U” shape when viewed in cross-section. They consist of a flat base with two parallel flanges extending upward, forming a U-shaped profile. The design of hat channels provides strength, rigidity, and sound-dampening properties.

The hat channel roll forming machine operates similarly to other roll forming machines. It consists of a series of forming stations equipped with roller dies that progressively shape a metal strip into the desired hat channel profile. The rollers gradually bend and form the metal strip, accurately controlling the dimensions and features of the hat channel.

Depending on the specific application, the hat channel roll forming machine may include additional stations for punching holes, embossing patterns, or adding other features to the channel. These variations allow for customization to meet specific project requirements.

By utilizing a hat channel roll forming machine, manufacturers can produce hat channels in high volume with consistent quality and precise dimensions. The automation and precision of the machine enable efficient production, making it a valuable tool in the construction industry.

बिक्री के लिए मेटल स्टड और ट्रैक रोल बनाने की मशीन जो आपके शीट मेटल के तरीके को बदल सकती है

आज बिक्री के लिए मेटल स्टड रोल बनाने की मशीन में निवेश करने के 5 कारण